10 月 . 19, 2024 13:42 Back to list

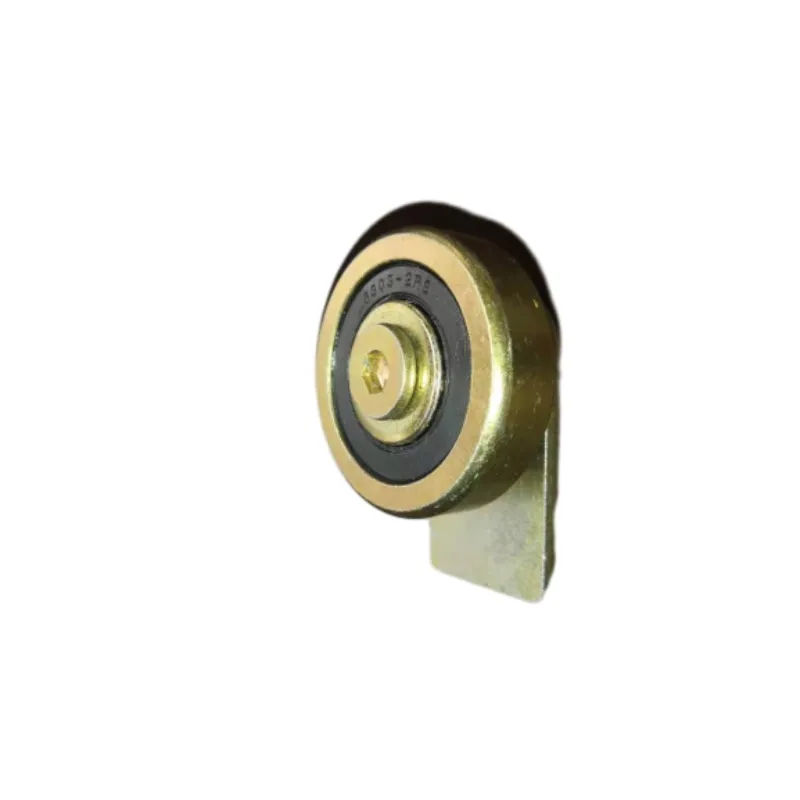

12mm thrust bearing

Understanding 12mm Thrust Bearings Applications and Advantages

Thrust bearings are crucial components in the machinery and mechanical systems that require the ability to withstand axial loads. Among the various types of thrust bearings available, the 12mm thrust bearing is particularly noteworthy due to its unique specifications and versatile applications. In this article, we will delve into the workings of a 12mm thrust bearing, its benefits, typical applications, and factors to consider when choosing one for your needs.

What is a Thrust Bearing?

A thrust bearing is designed to support axial loads, which are forces that act parallel to the axis of rotation. Unlike radial bearings, which handle vertical or lateral loads, thrust bearings are specifically constructed to carry loads that act along the shaft. This makes them essential in systems where the rotating element must maintain its position while supporting additional weight.

Features of 12mm Thrust Bearings

The designation 12mm refers to the inner diameter of the bearing, meaning it is designed to fit on shafts or components with a 12mm diameter. Thrust bearings come in various sizes and configurations, including washer-type and cylindrical designs. Depending on the specific design, a 12mm thrust bearing can comprise different materials, such as steel, bronze, or even plastic, each offering unique benefits.

One of the defining characteristics of a 12mm thrust bearing is its load capacity. While a smaller diameter may limit the overall load it can bear compared to larger options, it is perfectly suited for applications where space and weight are constraints. The bearing's design allows it to reduce friction efficiently, enabling smoother operations even under significant axial loads.

Advantages of Using 12mm Thrust Bearings

1. Compact Size The 12mm diameter makes these bearings ideal for space-sensitive applications, such as robotics or compact machinery. Their compact design does not compromise performance, allowing for efficient weight distribution.

2. Durability High-quality materials used in the construction of 12mm thrust bearings ensure longevity and resistance to wear. They can withstand regular use in demanding environments, providing reliable performance over time.

12mm thrust bearing

3. Smooth Operation With lower friction levels compared to other components, these bearings enable smoother operating conditions. This results in less heat production and reduced energy loss during operation.

4. Versatility Their design allows for a wide array of applications. Whether used in automotive, aerospace, or manufacturing sectors, 12mm thrust bearings perform efficiently where axial loads are prevalent.

5. Cost-Effective Solution Small bearings are often more affordable than larger alternatives, making them a cost-effective choice for manufacturers and engineers looking to optimize performance without excessive spending.

Applications of 12mm Thrust Bearings

12mm thrust bearings are utilized in various industries where axial loads need to be managed. Common applications include

- Automotive These bearings can be found in steering mechanisms and transmission assemblies where directional forces are at play. - Electric Motors In small electric motors, thrust bearings help maintain the rotor’s position while ensuring smooth rotation.

- Robotics In robotic joints and arms, 12mm thrust bearings provide support for the axial load generated during motion.

- Industrial Machinery Manufacturing equipment often requires thrust bearings to manage load in applications such as conveyors and presses.

Conclusion

In summary, the 12mm thrust bearing serves as a vital component in numerous mechanical systems requiring precise handling of axial loads. Its compact size, durability, and efficiency make it an attractive solution for various applications across multiple industries. When selecting a thrust bearing, it's essential to consider the specific requirements of your application, including load capacity, material, and rotational speed. With the proper choice, a 12mm thrust bearing can enhance the performance and longevity of your machinery, ensuring reliable operations for years to come.

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024