1 月 . 31, 2025 00:59 Back to list

16003 bearing dimensions

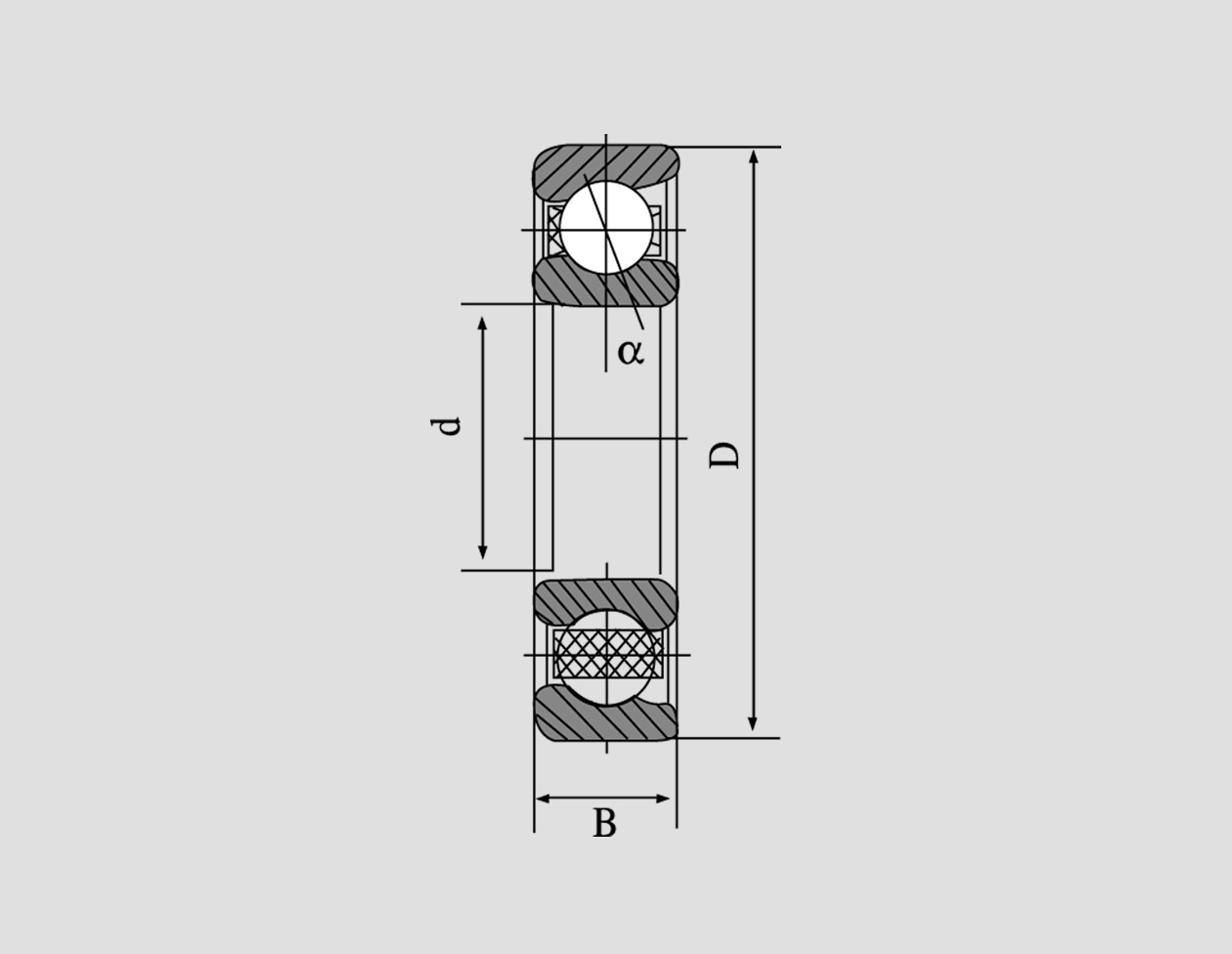

Exploring the intricate world of industrial components can lead one to the fascinating topic of bearing dimensions, specifically the 16003 bearing, a pivotal element in numerous mechanical applications. Understanding the dimensions and specifications of this particular bearing is essential not only for ensuring optimal performance but also for prolonging the lifespan of the equipment in which it is employed.

Lubrication is an often underestimated facet of bearing maintenance. For the 16003 bearing, regular inspection and replenishment of lubricant are vital. Greases with high thermal stability and low viscosity are preferred to preserve the bearing's ability to operate at high speeds without overheating. Correct lubrication minimizes friction, ultimately translating to energy savings and prolonged bearing life—critical factors in sustainable industrial practices. In selecting a 16003 bearing, one must also consider the dynamic and static load ratings. These ratings provide insight into the bearing's suitability for handling operational stresses. The dynamic load rating indicates the maximum load a bearing can sustain while rotating, while the static load rating refers to the maximum load it can hold without movement. Properly understanding these ratings ensures that the selected bearing meets the operational demands, safeguarding against premature failure due to overloading. Despite the durability and impressive load-handling abilities, all bearings, including the 16003, are susceptible to failure if improperly installed. Installation techniques should emphasize precision and care, ensuring alignment is correct and that no undue pressure is applied to the bearing. Misalignment during installation can lead to uneven load distribution, which could cause rapid wear or catastrophic failure. In conclusion, the 16003 bearing stands as a testament to engineering precision and reliability. Its dimensions and specifications make it an indispensable component in fast-paced industrial settings, where longevity, efficiency, and resilience are paramount. Understanding these elements and employing diligent maintenance practices can significantly enhance performance, ensuring that each component seamlessly contributes to the broader machinery assembly. Embracing these insights not only maximizes operational efficiency but also establishes a foundation of trust and expertise in mechanical applications.

Lubrication is an often underestimated facet of bearing maintenance. For the 16003 bearing, regular inspection and replenishment of lubricant are vital. Greases with high thermal stability and low viscosity are preferred to preserve the bearing's ability to operate at high speeds without overheating. Correct lubrication minimizes friction, ultimately translating to energy savings and prolonged bearing life—critical factors in sustainable industrial practices. In selecting a 16003 bearing, one must also consider the dynamic and static load ratings. These ratings provide insight into the bearing's suitability for handling operational stresses. The dynamic load rating indicates the maximum load a bearing can sustain while rotating, while the static load rating refers to the maximum load it can hold without movement. Properly understanding these ratings ensures that the selected bearing meets the operational demands, safeguarding against premature failure due to overloading. Despite the durability and impressive load-handling abilities, all bearings, including the 16003, are susceptible to failure if improperly installed. Installation techniques should emphasize precision and care, ensuring alignment is correct and that no undue pressure is applied to the bearing. Misalignment during installation can lead to uneven load distribution, which could cause rapid wear or catastrophic failure. In conclusion, the 16003 bearing stands as a testament to engineering precision and reliability. Its dimensions and specifications make it an indispensable component in fast-paced industrial settings, where longevity, efficiency, and resilience are paramount. Understanding these elements and employing diligent maintenance practices can significantly enhance performance, ensuring that each component seamlessly contributes to the broader machinery assembly. Embracing these insights not only maximizes operational efficiency but also establishes a foundation of trust and expertise in mechanical applications.

Next:

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024