12 月 . 05, 2024 19:49 Back to list

Exploring the Applications and Specifications of 32213 Bearing in Mechanical Systems

Understanding the 32213 Bearing A Comprehensive Overview

In the world of mechanical engineering and machinery, the importance of bearings cannot be overstated. They play a crucial role in ensuring the smooth operation of rotating components, thereby minimizing friction and wear. One such widely used bearing type is the 32213 bearing. This article delves into the specifications, applications, advantages, and maintenance tips for the 32213 bearing, aiming to provide a comprehensive understanding of this essential mechanical component.

What is a 32213 Bearing?

The designation 32213 refers to a specific type of taper roller bearing. Taper roller bearings are designed to support both radial and axial loads, thanks to their unique design that features conical rollers arranged in a manner that allows them to handle forces from multiple directions.

The numerical designation can provide valuable information about the dimensions and design characteristics of the bearing. For instance, in the case of the 32213 bearing, the 32 refers to the series that follows a specific standard established by the International Organization for Standardization (ISO). The 213 part indicates the size and the load-carrying capacity of the bearing. The 32213 bearing typically has a bore diameter of 65 mm, an outer diameter of 120 mm, and a width of approximately 33 mm, making it a medium-sized bearing suitable for various applications.

Common Applications

The versatility of the 32213 bearing means it finds its way into a wide range of applications. One of the most common uses of this bearing type is in automotive applications, where they are utilized in wheel hubs and transmissions. The ability to manage radial and axial loads makes them ideal for components that experience both types of stress during operation.

In addition to automotive applications, the 32213 bearing is employed in industrial machinery, construction equipment, and agricultural machinery. Their robust design allows them to operate effectively in demanding environments, catering to the needs of heavy-duty applications. Moreover, these bearings are often used in electric motors and gear systems, where precision and durability are key to optimal performance.

Advantages of 32213 Bearings

One of the standout features of the 32213 bearing is its ability to handle high radial loads while also accommodating axial loads. This dual capability makes it an indispensable component for machinery that experiences varied load conditions. Furthermore, taper roller bearings, including the 32213, are known for their durability and long lifespan, provided they are adequately maintained.

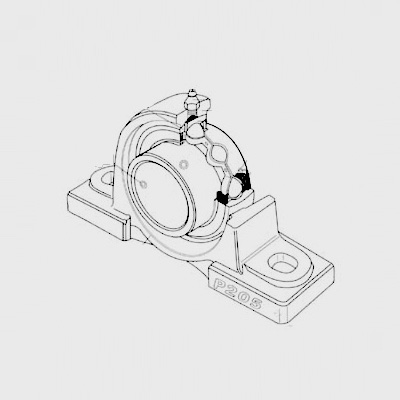

32213 bearing

Another advantage of the 32213 bearing is its relatively simple installation process. The tapered design allows for easy adjustment and alignment, ensuring that the bearing can be installed accurately within a machinery setup. Additionally, because taper roller bearings can be easily disassembled for maintenance or replacement, they offer convenience for technicians and engineers in the field.

Maintenance Tips

To ensure the longevity and proper functioning of the 32213 bearing, regular maintenance is crucial. Here are several key maintenance tips

1. Regular Lubrication Bearings require proper lubrication to minimize friction and heat generation. Depending on the application, a suitable grease or oil should be applied periodically.

2. Inspect for Wear Routine inspections can help identify signs of wear, including pitting or scoring on the raceways or rolling elements. Addressing these issues early can prevent further damage.

3. Monitor Operating Conditions Keep an eye on the operating temperature and load conditions. Operating outside the specified limits can lead to premature bearing failure.

4. Proper Installation Ensure that the bearing is installed according to the manufacturer's guidelines. Incorrect installation can lead to misalignment and subsequent failure.

5. Contaminant Prevention Protect the bearing from dust and debris, which can lead to contamination and accelerated wear. Use sealing solutions when applicable.

Conclusion

The 32213 bearing is an essential component in many mechanical systems, valued for its ability to endure high loads and provide reliable performance. Its applications span various industries, from automotive to heavy machinery, thanks to its robust design and ease of maintenance. By understanding its specifications, advantages, and maintenance requirements, engineers and technicians can ensure optimal functioning and prolong the lifespan of this critical mechanical part. Whether in a factory, on a construction site, or in a vehicle, the 32213 bearing plays a pivotal role in keeping the wheels of industry turning smoothly.

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024