1 月 . 21, 2025 01:15 Back to list

6200 zz

Bearings are integral to a myriad of machinery and applications ranging from automotive components to industrial machinery. The 6200 ZZ bearing, in particular, stands out for its versatile nature and robust functionality, making it a critical component worthy of detailed exploration. Drawing from professional expertise and real-world experience, this article unravels the intricacies of the 6200 ZZ bearing, highlighting its technical specifications, applications, benefits, and optimized usage.

In optimizing the application of 6200 ZZ bearings in equipment, it's essential to consider environmental factors and load requirements. Proper alignment during installation minimizes undue stress, thereby enhancing longevity and performance. Furthermore, while the ZZ shields provide significant protection against contaminants, ensuring that the operational environment is as clean as possible will maximize bearing lifespan. One cannot overlook the profound cost efficiency presented by the 6200 ZZ bearing. Its widespread availability is a result of both its popularity and the reliable performance it offers across diverse industries. Companies invested in prolonging equipment life without escalating maintenance costs often opt for these bearings. This practical insight, drawn from industry experience, is critical in making informed purchasing decisions. In summary, the 6200 ZZ bearing represents a blend of technical prowess and practical ingenuity. Its dimensions and shielding make it indispensable in a wide array of applications, shaped by the authoritative knowledge of both scientists and engineers who continually refine bearing technology. As professionals encounter evolving technological demands, the 6200 ZZ bearing consistently proves its mettle as a durable, reliable, and cost-effective solution. By leveraging the remarkable attributes of the 6200 ZZ bearing, industries can ensure high performance and efficacy in their machinery operations, supporting both industrial and consumer advancements with a trusted bearing solution.

In optimizing the application of 6200 ZZ bearings in equipment, it's essential to consider environmental factors and load requirements. Proper alignment during installation minimizes undue stress, thereby enhancing longevity and performance. Furthermore, while the ZZ shields provide significant protection against contaminants, ensuring that the operational environment is as clean as possible will maximize bearing lifespan. One cannot overlook the profound cost efficiency presented by the 6200 ZZ bearing. Its widespread availability is a result of both its popularity and the reliable performance it offers across diverse industries. Companies invested in prolonging equipment life without escalating maintenance costs often opt for these bearings. This practical insight, drawn from industry experience, is critical in making informed purchasing decisions. In summary, the 6200 ZZ bearing represents a blend of technical prowess and practical ingenuity. Its dimensions and shielding make it indispensable in a wide array of applications, shaped by the authoritative knowledge of both scientists and engineers who continually refine bearing technology. As professionals encounter evolving technological demands, the 6200 ZZ bearing consistently proves its mettle as a durable, reliable, and cost-effective solution. By leveraging the remarkable attributes of the 6200 ZZ bearing, industries can ensure high performance and efficacy in their machinery operations, supporting both industrial and consumer advancements with a trusted bearing solution.

Next:

Latest news

-

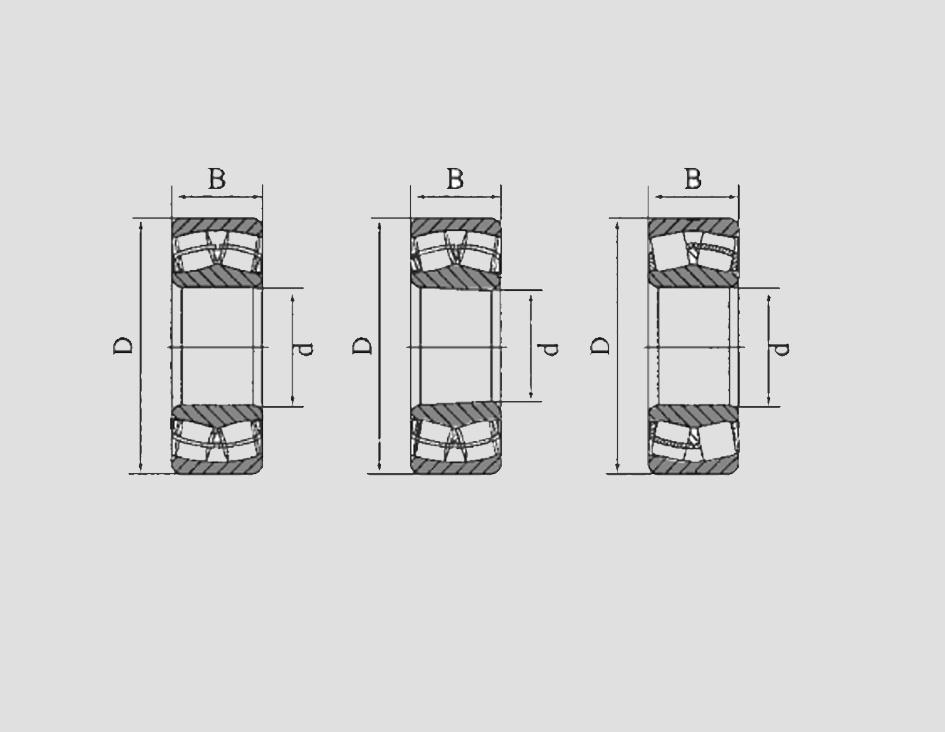

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024