2 月 . 10, 2025 10:09 Back to list

deep groove ball bearing

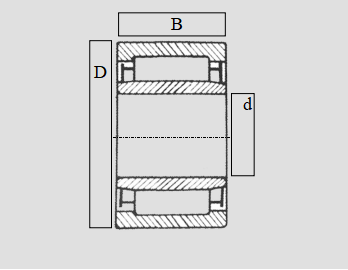

Understanding the dimensions and specifications of machine components is crucial, especially when dealing with something as vital as the 6202 bearing. This bearing is known for its versatility and is commonly utilized in a range of machinery, from household appliances to automotive applications. Here's an in-depth exploration of why the 6202 bearing holds significant importance, particularly its dimensions in millimeters, and what makes this bearing a reliable choice.

For engineers and technicians, the trustworthiness of the 6202 bearing is further solidified by its performance under dynamic conditions. In the area of precision applications, where inconsistencies can disrupt entire systems, having a bearing that promises uniformity and reliability is invaluable. Such reliability is why leading manufacturers align their quality assurance processes with international standards when producing the 6202 bearing. This adherence not only guarantees compatibility but also affirms trust in performance across a myriad of applications. When considering replacements or upgrades in mechanical systems, understanding the nuances of the 6202 bearing's specifications is critical. Each measurement, from the 15 mm inner diameter to the total width, affects the application’s efficiency and the bearing’s functionality. A purchasing decision informed by these technical insights can significantly enhance operational capabilities while reducing unnecessary downtimes due to part failures. In conclusion, the 6202 bearing is more than just a component in machinery; it is a cornerstone of operational efficiency and longevity. Its meticulously engineered dimensions, combined with the durability and trust it commands across industries, makes it an indispensable element in engineering applications. By choosing the 6202 bearing, professionals are not only investing in a product but also in the assurance of performance, backed by years of engineering excellence.

For engineers and technicians, the trustworthiness of the 6202 bearing is further solidified by its performance under dynamic conditions. In the area of precision applications, where inconsistencies can disrupt entire systems, having a bearing that promises uniformity and reliability is invaluable. Such reliability is why leading manufacturers align their quality assurance processes with international standards when producing the 6202 bearing. This adherence not only guarantees compatibility but also affirms trust in performance across a myriad of applications. When considering replacements or upgrades in mechanical systems, understanding the nuances of the 6202 bearing's specifications is critical. Each measurement, from the 15 mm inner diameter to the total width, affects the application’s efficiency and the bearing’s functionality. A purchasing decision informed by these technical insights can significantly enhance operational capabilities while reducing unnecessary downtimes due to part failures. In conclusion, the 6202 bearing is more than just a component in machinery; it is a cornerstone of operational efficiency and longevity. Its meticulously engineered dimensions, combined with the durability and trust it commands across industries, makes it an indispensable element in engineering applications. By choosing the 6202 bearing, professionals are not only investing in a product but also in the assurance of performance, backed by years of engineering excellence.

Next:

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024