11 月 . 02, 2024 04:57 Back to list

6204 bearing specifications

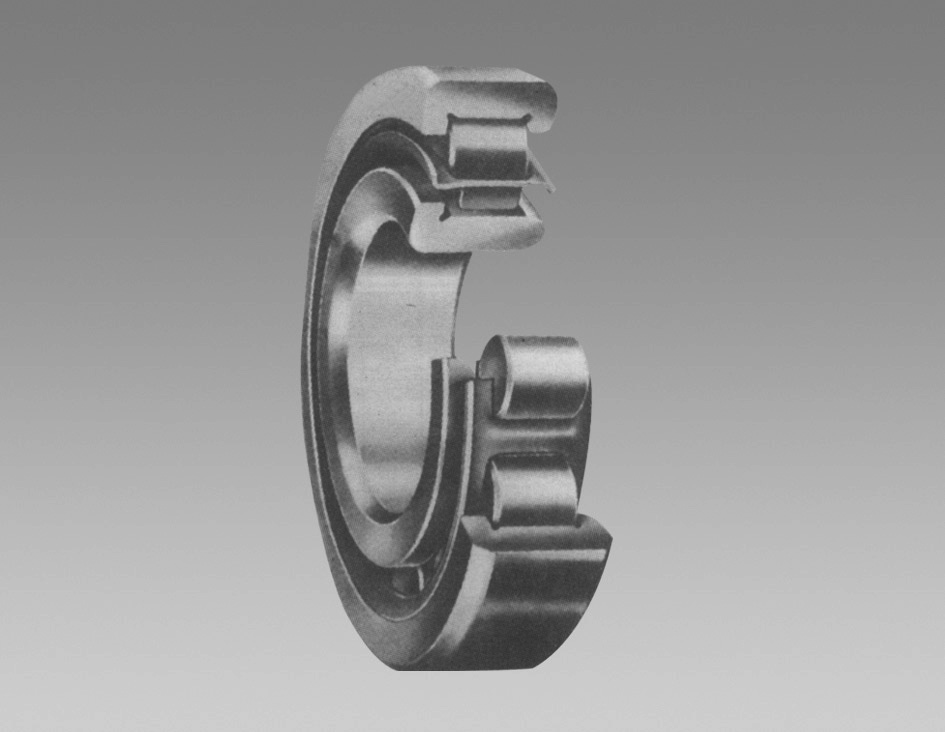

Understanding the 6204 Bearing Specifications

Bearings are crucial components in various machines and equipment, enabling smooth and efficient operation by reducing friction between moving parts. Among the numerous types of bearings available, the 6204 bearing has gained prominence due to its versatility and reliable performance across various applications. This article delves into the specifications, features, and applications of the 6204 bearing, offering insights into why it remains a popular choice in the engineering and manufacturing fields.

Basic Specifications

The 6204 bearing is classified as a deep groove ball bearing, primarily designed to accommodate both radial and axial loads. Its primary specifications include an inner diameter of 20 mm, an outer diameter of 47 mm, and a thickness (or width) of 14 mm. These dimensions make it suitable for a variety of applications, as it provides a balance between load capacity and compactness.

The 6204 bearing typically utilizes steel as its primary material, offering durability and the ability to withstand various load conditions. Additionally, it may be sealed or shielded on one or both sides to prevent the ingress of dirt and moisture, which could significantly impact its performance and lifespan.

Load Ratings

One of the critical aspects of any bearing is its load rating, and the 6204 bearing is no exception. It generally has a dynamic load rating of around 10,600 N and a static load rating of approximately 5,700 N. This load capacity means that the 6204 can handle substantial forces, making it ideal for applications where both radial and axial loads are present. Understanding the load ratings is crucial for selecting the right bearing for specific applications, as exceeding these limits can lead to premature wear or failure.

6204 bearing specifications

Operating Conditions and Temperature Range

The 6204 bearing is designed to operate effectively in various environmental conditions. Its standard operating temperature range is typically from -30°C to +120°C. However, with appropriate lubrication and the right materials (such as ceramics or specialized plastics), it can operate in more extreme conditions. This range ensures that the 6204 bearing remains functional and reliable in diverse industrial applications, from electric motors to pump systems.

Applications

The versatility of the 6204 bearing makes it suitable for numerous applications across various industries. Common uses include

- Automotive Found in wheels, transmissions, and other rotating components. - Electric Motors Widely used in motors for its ability to handle both radial and axial loads effectively. - Home Appliances Employed in devices such as washing machines and vacuum cleaners. - Industrial Machinery Crucial in conveyor systems, pumps, and fans, where reliable rotation is essential.

Conclusion

The 6204 bearing represents a reliable and adaptable solution for numerous engineering and manufacturing needs. Its standard dimensions, impressive load capacities, and ability to operate under various conditions underscore its significance in both industrial and consumer applications. Understanding its specifications not only aids in selecting the right bearing for a given task but also ensures optimal performance and longevity of the machinery it supports. With continued advancements in bearing technology, products like the 6204 will remain integral to innovation in various sectors, driving efficiency and reliability in mechanical systems.

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024