2 月 . 11, 2025 16:14 Back to list

6214 bearing dimensions

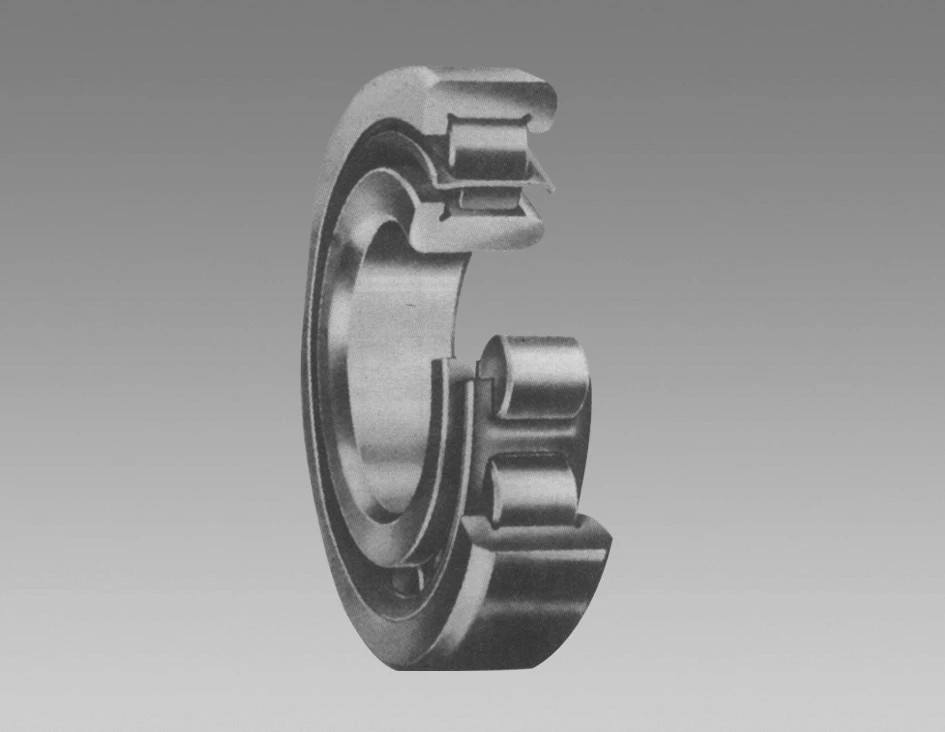

When it comes to mechanical components crucial for smooth operations in various industrial applications, bearings stand out for their indispensable role. Among many types, the 6214 bearing is widely recognized for its balance of performance and versatility. But what are the defining dimensions and characteristics that make the 6214 a go-to option across many sectors? By delving deep into these specifications, we can better understand its relevance and application.

Another noteworthy characteristic of the 6214 bearing is its ability to accommodate slight misalignments without significant performance degradation. This self-alignment feature is important, especially in applications where shafts may experience deflections, ensuring that the operations continue smoothly without premature failure. For ease of installation and maintenance, the 6214 bearing often comes pre-lubricated. This feature is crucial for reducing initial setup time and ensures lubrication consistency throughout its operational life. Additionally, the bearing’s seals or shields provide added protection, enhancing its operational lifespan by blocking contaminant ingress. In terms of application, 6214 bearings find usage in an expansive range of industries. From small machinery in the agricultural sector to conveyor belts and pumps in the manufacturing landscape, the 6214’s adaptable dimensions and durable design make it a staple choice. Its ability to reduce operational downtime and maintenance costs offers tangible benefits that industry professionals highly appreciate. Choosing the right bearing dimensions is pivotal for achieving optimal machine performance and minimizing mechanical failure risks. The 6214 bearing exemplifies how precise dimensions, coupled with high-quality materials and design, can offer reliability, performance efficiency, and operational longevity. When selecting bearings, it’s crucial to consult with experts or refer to manufacturer specifications to ensure that the bearing’s dimensions and materials align with the specific requirements of the application in question. The 6214’s blend of design, durability, and performance stands as a testament to its enduring appeal and functionality across various industrial applications.

Another noteworthy characteristic of the 6214 bearing is its ability to accommodate slight misalignments without significant performance degradation. This self-alignment feature is important, especially in applications where shafts may experience deflections, ensuring that the operations continue smoothly without premature failure. For ease of installation and maintenance, the 6214 bearing often comes pre-lubricated. This feature is crucial for reducing initial setup time and ensures lubrication consistency throughout its operational life. Additionally, the bearing’s seals or shields provide added protection, enhancing its operational lifespan by blocking contaminant ingress. In terms of application, 6214 bearings find usage in an expansive range of industries. From small machinery in the agricultural sector to conveyor belts and pumps in the manufacturing landscape, the 6214’s adaptable dimensions and durable design make it a staple choice. Its ability to reduce operational downtime and maintenance costs offers tangible benefits that industry professionals highly appreciate. Choosing the right bearing dimensions is pivotal for achieving optimal machine performance and minimizing mechanical failure risks. The 6214 bearing exemplifies how precise dimensions, coupled with high-quality materials and design, can offer reliability, performance efficiency, and operational longevity. When selecting bearings, it’s crucial to consult with experts or refer to manufacturer specifications to ensure that the bearing’s dimensions and materials align with the specific requirements of the application in question. The 6214’s blend of design, durability, and performance stands as a testament to its enduring appeal and functionality across various industrial applications.

Next:

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024