2 月 . 12, 2025 20:21 Back to list

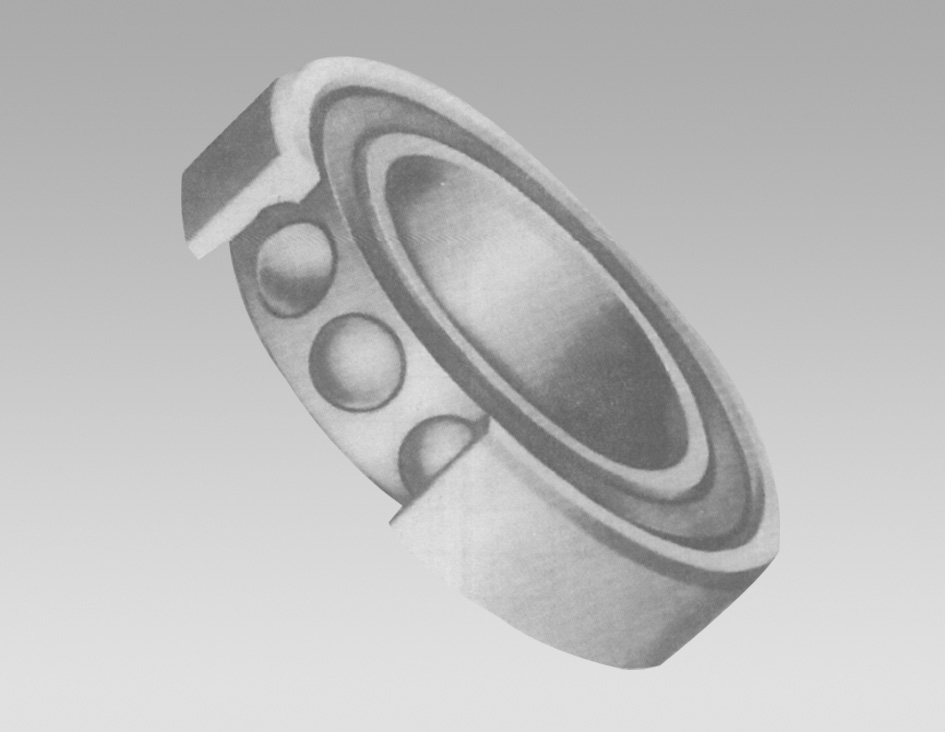

628 2rs bearing

The 628 2RS bearing, a pivotal component in various mechanical applications, exemplifies engineering perfection and reliability. As industries continue to evolve, the demand for efficient and robust bearings like the 628 2RS remains indispensable. Whether you are an engineer in a bustling workshop or a hobbyist creating precision models, understanding and utilizing these bearings can significantly enhance the efficiency and lifespan of your projects.

Authoritativeness in the realm of bearings like the 628 2RS is crucial, especially in industries where reliability is paramount. Leading manufacturers and suppliers designate rigorous testing and quality assurance processes to ensure each bearing meets international standards. For users, selecting bearings from reputable brands guarantees peace of mind, knowing that the component has undergone stringent evaluations for performance and durability. Trustworthiness, a key parameter for components exposed to intensive usage conditions, solidifies the 628 2RS bearing's reputation. Its proven track record in diverse applications stands testament to its dependability. Moreover, the bearing's design incorporates resilience against wear and fatigue, which are common failure points. Businesses and technicians have shared stories where the longevity and reliability of these bearings led to reduced downtimes and cost savings, thereby affirming its credibility over time. In optimizing product performance, understanding the nuances of the 628 2RS bearing can lead to better application outcomes. Regular maintenance, though minimal due to its sealed nature, involves inspecting for signs of wear or contamination. Given its durability, the probability of failure due to material fatigue is low, but routine checks can further prolong its lifespan. In summary, the 628 2RS bearing represents a confluence of engineering prowess and reliability. Its design principles emphasize longevity, reduced friction, and protection against external contaminants. For engineers, mechanics, and hobbyists alike, opting for the 628 2RS means investing in a component that not only meets but exceeds expectations in performance and durability. As industries continue their relentless march towards efficiency and precision, components like the 628 2RS bearing are not merely parts—they are pillars that uphold the integrity and performance of countless mechanical marvels across the globe.

Authoritativeness in the realm of bearings like the 628 2RS is crucial, especially in industries where reliability is paramount. Leading manufacturers and suppliers designate rigorous testing and quality assurance processes to ensure each bearing meets international standards. For users, selecting bearings from reputable brands guarantees peace of mind, knowing that the component has undergone stringent evaluations for performance and durability. Trustworthiness, a key parameter for components exposed to intensive usage conditions, solidifies the 628 2RS bearing's reputation. Its proven track record in diverse applications stands testament to its dependability. Moreover, the bearing's design incorporates resilience against wear and fatigue, which are common failure points. Businesses and technicians have shared stories where the longevity and reliability of these bearings led to reduced downtimes and cost savings, thereby affirming its credibility over time. In optimizing product performance, understanding the nuances of the 628 2RS bearing can lead to better application outcomes. Regular maintenance, though minimal due to its sealed nature, involves inspecting for signs of wear or contamination. Given its durability, the probability of failure due to material fatigue is low, but routine checks can further prolong its lifespan. In summary, the 628 2RS bearing represents a confluence of engineering prowess and reliability. Its design principles emphasize longevity, reduced friction, and protection against external contaminants. For engineers, mechanics, and hobbyists alike, opting for the 628 2RS means investing in a component that not only meets but exceeds expectations in performance and durability. As industries continue their relentless march towards efficiency and precision, components like the 628 2RS bearing are not merely parts—they are pillars that uphold the integrity and performance of countless mechanical marvels across the globe.

Next:

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024