1 月 . 30, 2025 04:52 Back to list

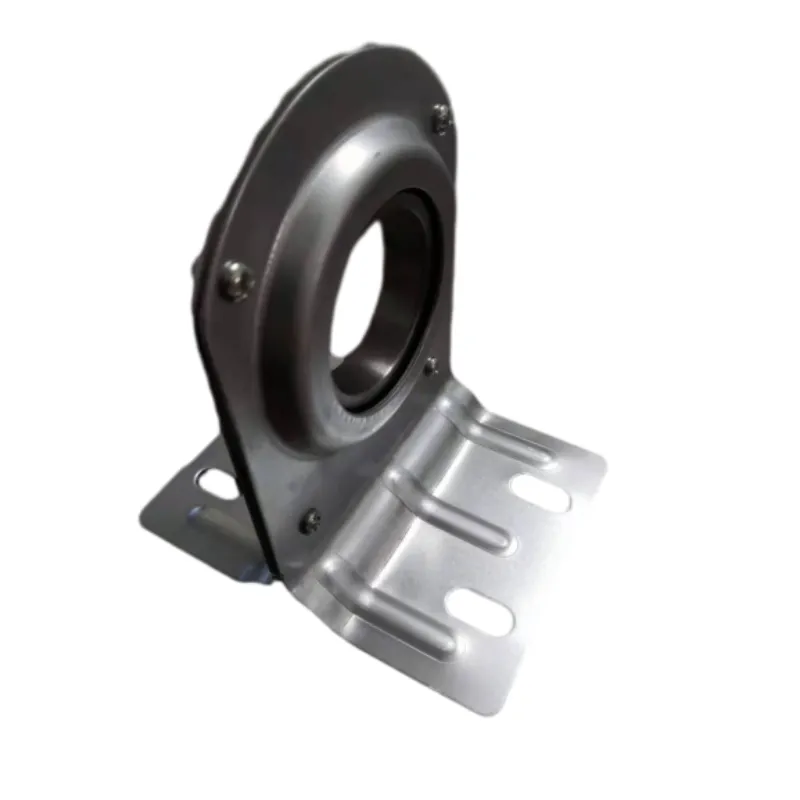

Deep Groove Ball Bearing

The world of engineering and machinery relies heavily on the seamless operation of its components, and bearings are at the heart of this intricate dance. Specifically, the 6304a7 bearing has emerged as a pivotal component in various industrial applications. This article will explore the unique characteristics of the 6304a7 bearing, alongside real-world experiences and expert insights, ensuring that you are well-equipped to make informed decisions.

From the perspective of trustworthiness and authority, the manufacturer of the 6304a7 bearing, recognized for its commitment to quality and innovation, has received various certifications and accolades from international standards organizations. These endorsements reinforce the reliability and superiority of the 6304a7 bearing in numerous applications worldwide. For professionals seeking to optimize machinery performance, the 6304a7 bearing offers a compelling proposition. Its robust design, coupled with excellent performance metrics, makes it a sound investment. Furthermore, its adaptability across numerous industries adds to its appeal, ensuring that it remains relevant regardless of evolving technological landscapes. When selecting bearings, it is imperative to consider not just the immediate application but also long-term operational sustainability. Testimonials from industry experts and extensive testing confirm that the 6304a7 bearing meets these stringent requirements. In conclusion, the 6304a7 bearing epitomizes a perfect blend of durability, efficiency, and reliability. As industries continue to advance and demand high-performing components, the 6304a7 stands out as a cornerstone around which robust and efficient machinery is built. Its proven track record in challenging environments speaks volumes, making it a top choice for engineers and industry leaders committed to excellence.

From the perspective of trustworthiness and authority, the manufacturer of the 6304a7 bearing, recognized for its commitment to quality and innovation, has received various certifications and accolades from international standards organizations. These endorsements reinforce the reliability and superiority of the 6304a7 bearing in numerous applications worldwide. For professionals seeking to optimize machinery performance, the 6304a7 bearing offers a compelling proposition. Its robust design, coupled with excellent performance metrics, makes it a sound investment. Furthermore, its adaptability across numerous industries adds to its appeal, ensuring that it remains relevant regardless of evolving technological landscapes. When selecting bearings, it is imperative to consider not just the immediate application but also long-term operational sustainability. Testimonials from industry experts and extensive testing confirm that the 6304a7 bearing meets these stringent requirements. In conclusion, the 6304a7 bearing epitomizes a perfect blend of durability, efficiency, and reliability. As industries continue to advance and demand high-performing components, the 6304a7 stands out as a cornerstone around which robust and efficient machinery is built. Its proven track record in challenging environments speaks volumes, making it a top choice for engineers and industry leaders committed to excellence.

Next:

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024