2 月 . 13, 2025 15:40 Back to list

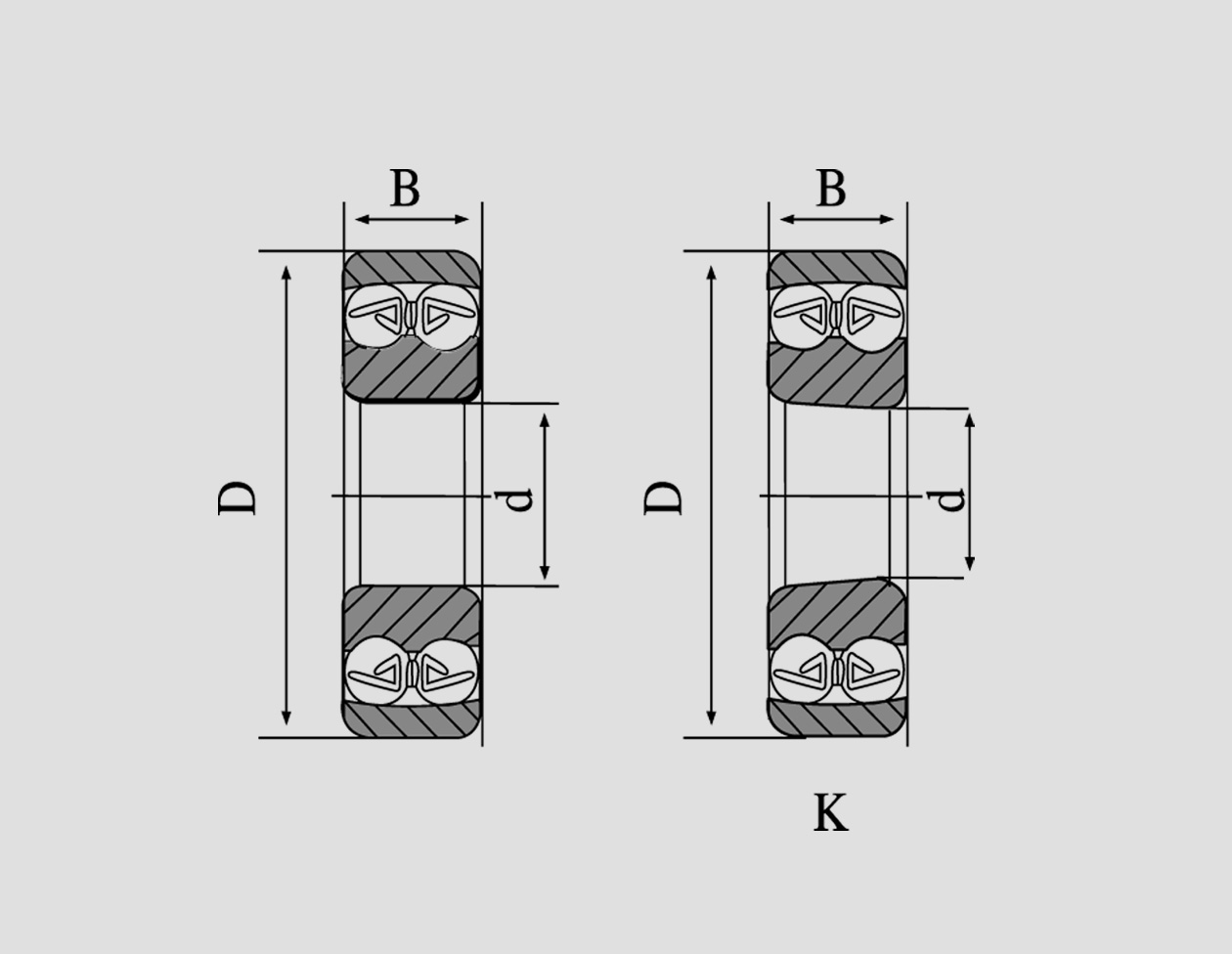

deep groove ball bearing specifications

The 6305 bearing stands as a pivotal component in numerous mechanical and industrial applications. As seasoned professionals in the field, we understand the significance of selecting the right bearing for specific needs. The 6305 bearing is a versatile piece, renowned for its balance of durability and efficiency.

For those seeking expert guidance on maintenance, consistently ensuring the longevity and optimal function of a 6305 bearing involves regular inspection and lubrication. Using the appropriate lubricant for the specific application environment prevents unnecessary wear and tear and contributes significantly to the bearing’s overall lifespan. Regular maintenance checks are advised to prevent unforeseen malfunctions and to sustain high-performance levels. In industrial applications, the compatibility of the 6305 bearing with other mechanical components is a testament to its authoritative position in engineering design. Its universal specifications mean it can seamlessly integrate into existing machinery without necessitating intricate adjustments or modifications, thereby minimizing downtime and enhancing operational efficiency. Trustworthiness in the realm of 6305 bearings also stems from the adherence to international manufacturing standards. Reputable manufacturers ensure compliance with rigorous standards, offering buyers confidence in the bearing’s performance and reliability. Knowing that the 6305 bearing meets or exceeds these standards provides peace of mind for engineers and designers who demand quality and precision. In conclusion, the 6305 bearing's impact is profound in providing solutions that require durability, flexibility, and high performance. Its specifications align with a range of industrial needs, offering engineers and professionals the assurance of a component that meets both current and future demands. For those in search of a bearing that delivers on all fronts, the 6305 is an exemplar of reliability and expertise in mechanical engineering. Its continued relevance in the marketplace speaks volumes about its design and execution, making it a cornerstone of many engineering applications.

For those seeking expert guidance on maintenance, consistently ensuring the longevity and optimal function of a 6305 bearing involves regular inspection and lubrication. Using the appropriate lubricant for the specific application environment prevents unnecessary wear and tear and contributes significantly to the bearing’s overall lifespan. Regular maintenance checks are advised to prevent unforeseen malfunctions and to sustain high-performance levels. In industrial applications, the compatibility of the 6305 bearing with other mechanical components is a testament to its authoritative position in engineering design. Its universal specifications mean it can seamlessly integrate into existing machinery without necessitating intricate adjustments or modifications, thereby minimizing downtime and enhancing operational efficiency. Trustworthiness in the realm of 6305 bearings also stems from the adherence to international manufacturing standards. Reputable manufacturers ensure compliance with rigorous standards, offering buyers confidence in the bearing’s performance and reliability. Knowing that the 6305 bearing meets or exceeds these standards provides peace of mind for engineers and designers who demand quality and precision. In conclusion, the 6305 bearing's impact is profound in providing solutions that require durability, flexibility, and high performance. Its specifications align with a range of industrial needs, offering engineers and professionals the assurance of a component that meets both current and future demands. For those in search of a bearing that delivers on all fronts, the 6305 is an exemplar of reliability and expertise in mechanical engineering. Its continued relevance in the marketplace speaks volumes about its design and execution, making it a cornerstone of many engineering applications.

Next:

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024