2 月 . 14, 2025 04:30 Back to list

deep groove ball bearing

The world of machinery and engineering relies heavily on components that ensure smooth and efficient operations. One such indispensable component is the 6310 ball bearing. This specific bearing is renowned for its efficiency across various applications, and understanding its features, uses, and benefits can significantly enhance one's grasp of mechanical engineering solutions.

From a technical standpoint, the balance between flexibility and rigidity offered by the 6310 bearing is exemplary. Its ability to handle slight misalignments while maintaining stability is crucial, especially in applications involving varying load directions. This adaptability not only makes it a versatile choice for different machinery but also a reliable one, promoting trust among engineers and maintenance personnel. Authoritative voices in the engineering world often endorse the use of 6310 ball bearings, citing their broad range of applications and resilience as key benefits. Studies and field reports consistently highlight their role in reducing energy consumption, attributed to the minimal resistance they offer, thus aligning with modern sustainability goals in industrial operations. Furthermore, users with hands-on experience frequently share testimonials about the bearings' ease of installation and replacement, which improves maintenance routines. This user-friendly nature underpins their widespread adoption, forming a compelling case for their inclusion in both existing and new mechanical setups. Building trust in 6310 ball bearings involves not just recognizing their engineering merits but also appreciating the wealth of operational experience they embody. Discussions among industry experts often include lubrication best practices and handling procedures that ensure the bearings' full potential is realized, all contributing to an informed and empowered user base. In an era where machinery excellence is defined by precision and reliability, the 6310 ball bearing stands out as a vital component that embodies these qualities. By combining innovative design, robust material selection, and expert manufacturing processes, this bearing continues to offer unmatched performance in demanding environments, solidifying its status as a cornerstone of mechanical excellence.

From a technical standpoint, the balance between flexibility and rigidity offered by the 6310 bearing is exemplary. Its ability to handle slight misalignments while maintaining stability is crucial, especially in applications involving varying load directions. This adaptability not only makes it a versatile choice for different machinery but also a reliable one, promoting trust among engineers and maintenance personnel. Authoritative voices in the engineering world often endorse the use of 6310 ball bearings, citing their broad range of applications and resilience as key benefits. Studies and field reports consistently highlight their role in reducing energy consumption, attributed to the minimal resistance they offer, thus aligning with modern sustainability goals in industrial operations. Furthermore, users with hands-on experience frequently share testimonials about the bearings' ease of installation and replacement, which improves maintenance routines. This user-friendly nature underpins their widespread adoption, forming a compelling case for their inclusion in both existing and new mechanical setups. Building trust in 6310 ball bearings involves not just recognizing their engineering merits but also appreciating the wealth of operational experience they embody. Discussions among industry experts often include lubrication best practices and handling procedures that ensure the bearings' full potential is realized, all contributing to an informed and empowered user base. In an era where machinery excellence is defined by precision and reliability, the 6310 ball bearing stands out as a vital component that embodies these qualities. By combining innovative design, robust material selection, and expert manufacturing processes, this bearing continues to offer unmatched performance in demanding environments, solidifying its status as a cornerstone of mechanical excellence.

Next:

Latest news

-

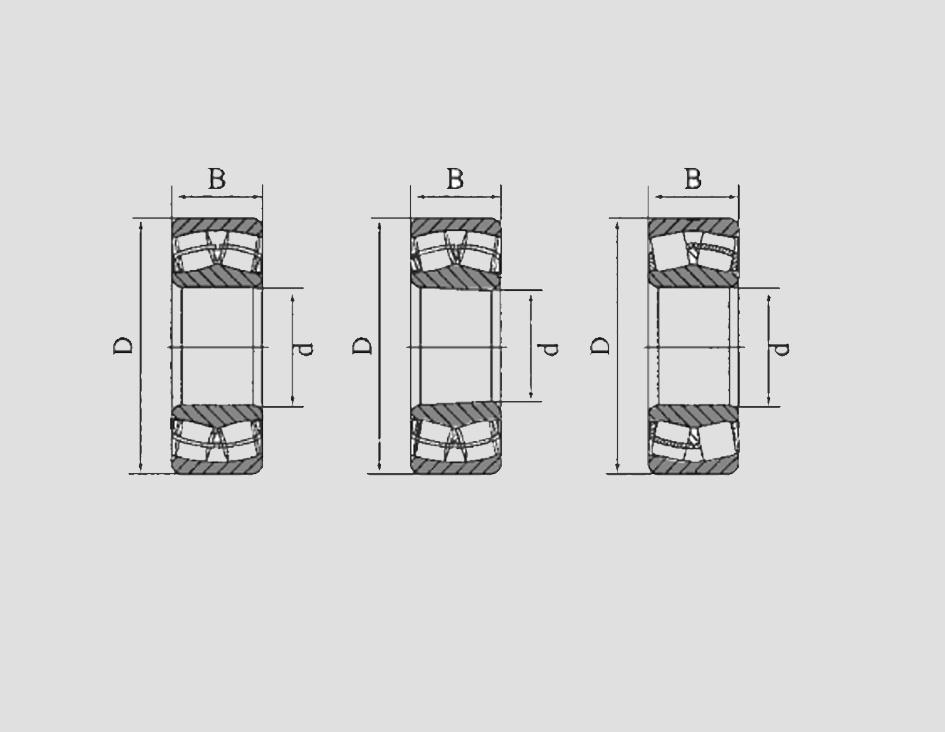

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024