10 月 . 06, 2024 09:29 Back to list

6319 bearing specifications

Understanding the Specifications of the 6319 Bearing

Bearings are crucial components in various mechanical systems, providing support for rotating or moving parts while reducing friction. Among the numerous types of bearings available, the 6319 bearing is noteworthy due to its robust design and widespread application in different industries. This article delves into the specifications, features, and applications of the 6319 bearing, offering insights into its significance in mechanical engineering.

Specifications of the 6319 Bearing

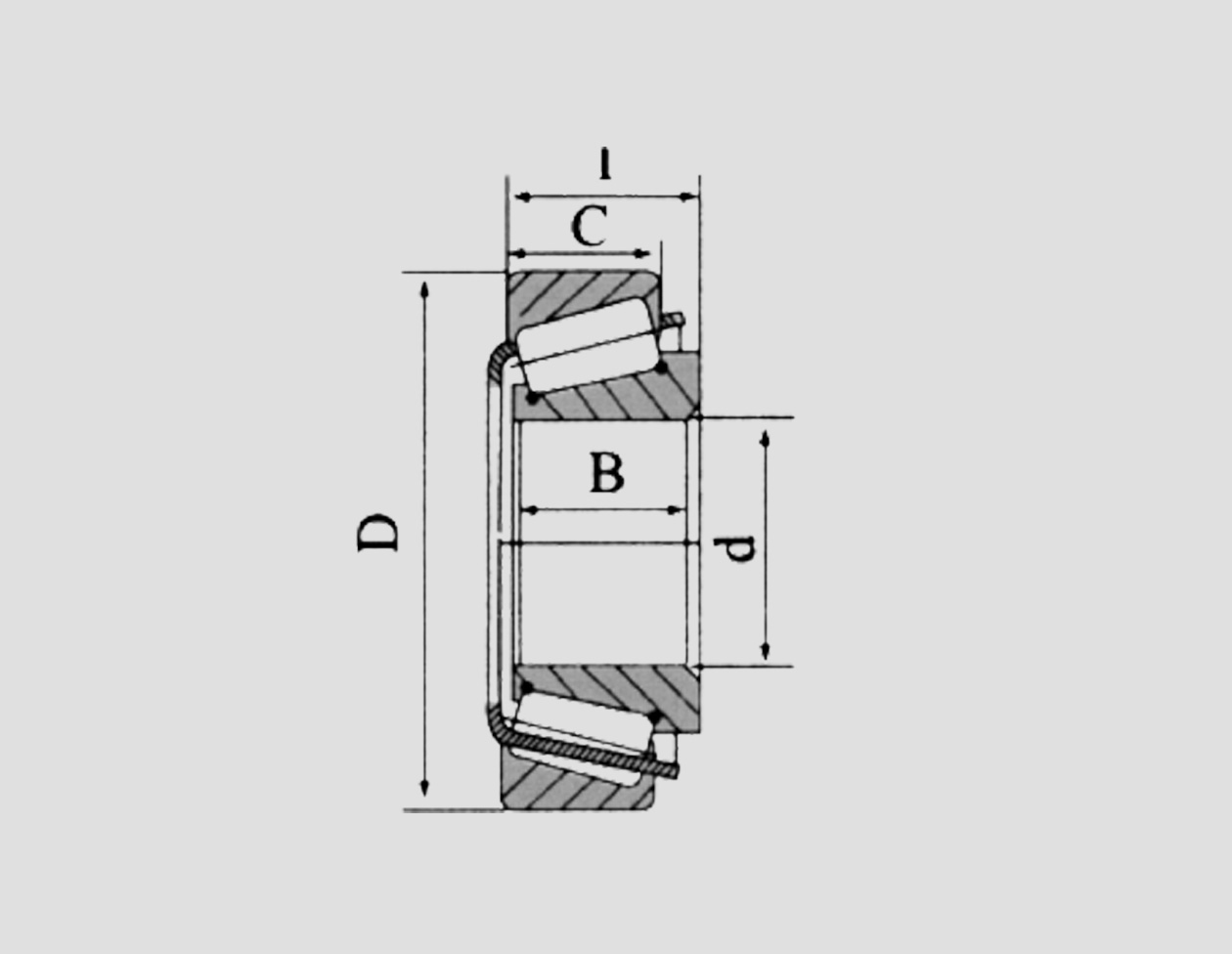

The 6319 bearing belongs to the deep groove ball bearing category, characterized by its ability to accommodate radial and axial loads in both directions. Here are the key specifications that define this bearing

1. Dimensions The 6319 bearing has an inner diameter of 95 mm, an outer diameter of 200 mm, and a width of 45 mm. These measurements make it suitable for various industrial applications, including those requiring high load capacity.

2. Load Ratings The dynamic load rating (C) for the 6319 bearing is approximately 108 kN, while the static load rating (C0) is about 70 kN. These ratings indicate the bearing’s capacity to handle applied loads without risk of failure.

3. Speed Ratings The 6319 bearing is designed to operate at high speeds, with a limiting speed of approximately 3,600 RPM when subjected to optimal conditions. This feature makes it ideal for applications involving rotary motion, such as electric motors and gearboxes.

4. Material Typically, the inner and outer rings of the 6319 bearing are made of high carbon chromium steel, providing excellent hardness and wear resistance. Additionally, the balls are often made of steel or ceramic, contributing to the overall durability and longevity of the bearing.

5. Sealing Options The 6319 bearing can come with various sealing options, including metal shields (ZZ) or rubber seals (2RS). These seals serve to protect the bearing from contaminants and retain lubrication, thereby enhancing its performance and life span.

Features of the 6319 Bearing

6319 bearing specifications

One of the primary features of the 6319 bearing is its versatility. It can be utilized in numerous applications due to its capacity to handle both radial and axial loads. Additionally, the deep groove design allows for the absorption of misalignment and shaft deflections, making it suitable for setups that experience varying operational conditions.

Another noteworthy feature is the bearing's low friction properties. The smooth surface finish and precision manufacturing ensure that the balls rotate with minimal resistance, thereby increasing energy efficiency in powered systems.

Applications of the 6319 Bearing

The 6319 bearing finds applications in a wide range of industries, including

- Manufacturing It is commonly used in conveyor systems, industrial machinery, and gearboxes, where reliable motion transfer and load support are essential.

- Automotive In vehicles, the 6319 bearing can be found in engines, transmissions, and wheel assemblies, contributing to smooth operation and performance.

- Aerospace Aircraft systems often utilize 6319 bearings in various components, including landing gears and turbine engines, where durability and reliability are critical.

- Electric Motors Many electric motors employ the 6319 bearing to support rotors and reduce friction during operation, thereby enhancing efficiency.

Conclusion

The 6319 bearing is a vital component that plays a significant role in the functionality of a range of mechanical systems. With its impressive specifications, versatile application potential, and ability to reduce friction, the 6319 bearing exemplifies the advancements in bearing technology. As industries continue to evolve and seek greater efficiency, the importance of such robust bearings will only increase, ensuring their continued relevance in engineering and manufacturing. Understanding the specifications and features of the 6319 bearing helps engineers and technicians make informed decisions when selecting bearings for their specific applications.

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024