11 月 . 04, 2024 07:28 Back to list

axial thrust bearing

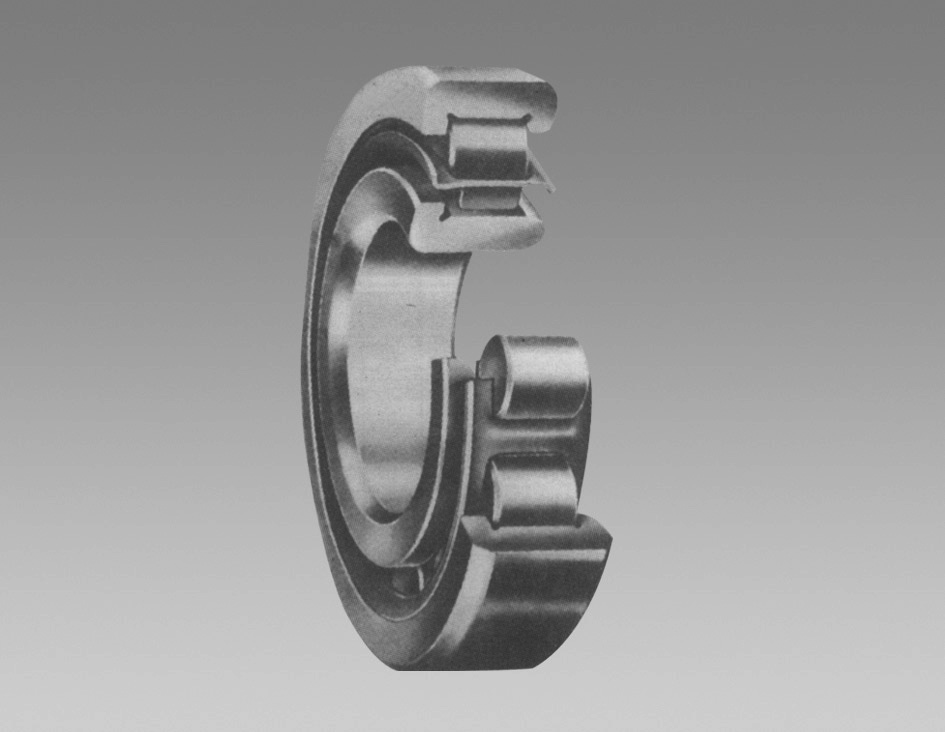

Understanding Axial Thrust Bearings Function, Design, and Applications

Axial thrust bearings are essential components in various mechanical systems, designed to manage axial loads and prevent unwanted movement along the axis of rotating equipment. Unlike traditional roller or ball bearings that handle radial loads, thrust bearings are specifically engineered to accommodate loads that are parallel to the axis of rotation. This specialized design is crucial in applications such as turbines, marine propellers, and electric motors, where precise movement and stability are paramount.

Function of Axial Thrust Bearings

The primary function of axial thrust bearings is to support and distribute axial loads effectively. These loads arise from forces directed along the shaft's axis, often due to rotational motion or changes in operational parameters. For instance, in a motor, the axial thrust bearing prevents the rotor from moving sideways, maintaining its alignment within the stator. This alignment is vital for optimal performance, as misalignment can lead to increased wear, reduced efficiency, and, ultimately, equipment failure.

Thrust bearings can be found in two main designs flat thrust bearings and collar thrust bearings. Flat thrust bearings typically consist of two flat surfaces where one surface rotates against the other. Conversely, collar thrust bearings incorporate a cylindrical shape that can better handle heavy loads, and they often include rolling elements, such as balls or rollers, to minimize friction and wear.

Design Considerations

axial thrust bearing

When designing axial thrust bearings, several factors must be taken into account. The most critical elements include the load capacity, material selection, lubrication, and operational environment. Load capacity dictates the maximum load the bearing can support without failure. Materials are chosen based on their strength, wear resistance, and compatibility with lubricants. Common materials include steel, brass, and composite materials, each offering unique benefits depending on the application.

Lubrication is another essential consideration. Proper lubrication reduces friction, dissipates heat, and prevents wear and tear. Depending on the application, lubricants can include grease, oil, or even solid lubricants in extreme environments. Additionally, the operating environment—such as temperature, moisture, and the presence of contaminants—plays a crucial role in selecting the appropriate bearing design and materials.

Applications of Axial Thrust Bearings

Axial thrust bearings find applications across a wide range of industries. In the aerospace sector, they are critical in jet engines, where they help control rotor position and stability under high RPMs. In marine applications, these bearings support propeller shafts, minimizing lateral movement and enhancing performance. Similarly, in the industrial sector, they are widely used in pumps, gearboxes, and various machinery, ensuring efficient operation and longevity.

In conclusion, axial thrust bearings are indispensable components in mechanical systems that deal with axial loads. Their unique design and function help ensure the proper alignment and operation of rotating equipment across diverse applications. As technology advances, the development of more efficient, durable, and adaptable thrust bearings will continue to enhance the performance and reliability of various mechanical systems, paving the way for innovations in engineering and manufacturing. Understanding their role and specifications is crucial for engineers and designers to select the right components for their specific applications, ultimately leading to safer and more efficient operations.

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024