2 月 . 15, 2025 20:43 Back to list

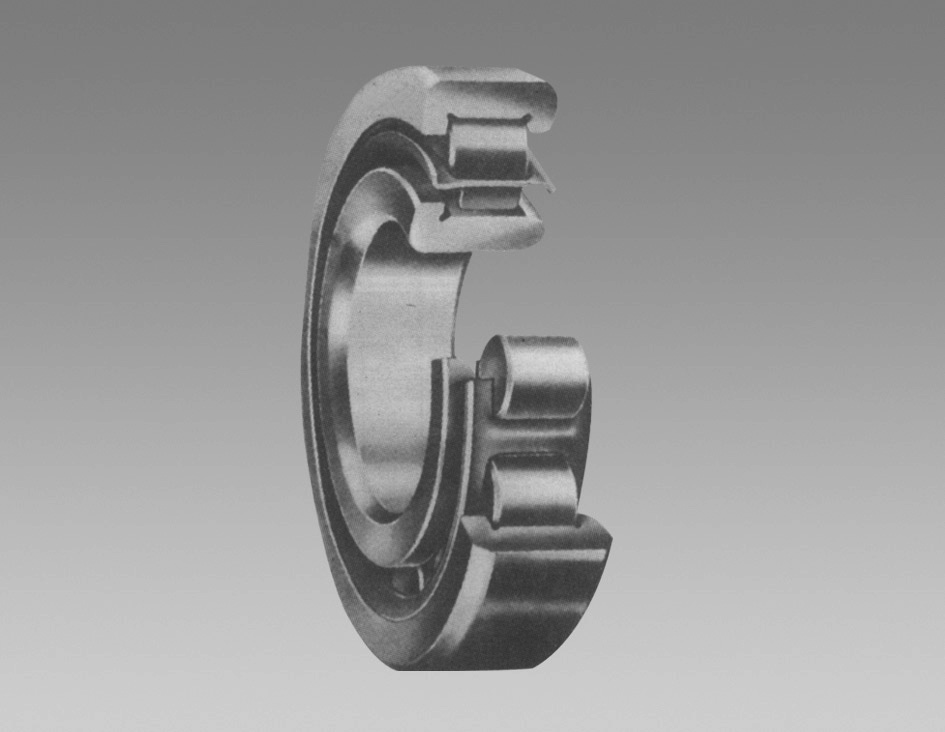

ball bearing 6014

Ball bearings are an essential component in numerous mechanical systems, serving as the backbone that ensures smooth rotational or linear movement between surfaces in contact. Among the plethora of bearing sizes and types available on the market, the 6014 ball bearing stands out due to its versatile applications, robust design, and unparalleled performance characteristics.

In terms of material composition, 6014 ball bearings are generally manufactured using high-grade chromium steel, which enhances their durability and corrosion resistance. The microstructure of this material ensures that even under challenging environmental conditions, such as exposure to moisture or chemical agents, the integrity of the bearing remains uncompromised. This contributes significantly to its authoritative acceptance in industries demanding high performance and longevity. Moreover, the trustworthiness of the 6014 ball bearing is further underscored by its compliance with international manufacturing standards. Suppliers typically provide detailed specifications and rigorous testing results, which validate the bearing's capability to meet exhaustive client demands across diverse applications. Guaranteeing familiarity with these standards not only builds confidence among engineers and technicians but also assures stakeholders of the component’s enduring quality. In practice, regular maintenance and appropriate lubrication play vital roles in extending the life expectancy of these bearings. Ensuring that bearings are correctly installed and consistently monitored helps prevent unexpected mechanical failures, thereby safeguarding operational efficiency. In scenarios where more extreme conditions are anticipated, selecting specialized 6014 variants—such as those with protective seals or additional corrosion-resistant coatings—can further enhance system robustness and reliability. In conclusion, the 6014 ball bearing is not merely another component—it represents a blend of engineering excellence, practical reliability, and functional adaptability. By offering sustained performance, and flexibility across industrial applications, and conforming to high standards of durability and trust, the 6014 bearing tape epitomizes the rigorous benchmarks of excellence that modern mechanical systems demand. When investing in quality and performance, the 6014 ball bearing offers unmatched value, proving indispensable in achieving precise mechanical harmony.

In terms of material composition, 6014 ball bearings are generally manufactured using high-grade chromium steel, which enhances their durability and corrosion resistance. The microstructure of this material ensures that even under challenging environmental conditions, such as exposure to moisture or chemical agents, the integrity of the bearing remains uncompromised. This contributes significantly to its authoritative acceptance in industries demanding high performance and longevity. Moreover, the trustworthiness of the 6014 ball bearing is further underscored by its compliance with international manufacturing standards. Suppliers typically provide detailed specifications and rigorous testing results, which validate the bearing's capability to meet exhaustive client demands across diverse applications. Guaranteeing familiarity with these standards not only builds confidence among engineers and technicians but also assures stakeholders of the component’s enduring quality. In practice, regular maintenance and appropriate lubrication play vital roles in extending the life expectancy of these bearings. Ensuring that bearings are correctly installed and consistently monitored helps prevent unexpected mechanical failures, thereby safeguarding operational efficiency. In scenarios where more extreme conditions are anticipated, selecting specialized 6014 variants—such as those with protective seals or additional corrosion-resistant coatings—can further enhance system robustness and reliability. In conclusion, the 6014 ball bearing is not merely another component—it represents a blend of engineering excellence, practical reliability, and functional adaptability. By offering sustained performance, and flexibility across industrial applications, and conforming to high standards of durability and trust, the 6014 bearing tape epitomizes the rigorous benchmarks of excellence that modern mechanical systems demand. When investing in quality and performance, the 6014 ball bearing offers unmatched value, proving indispensable in achieving precise mechanical harmony.

Next:

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024