2 月 . 16, 2025 03:15 Back to list

Deep Groove Ball Bearings

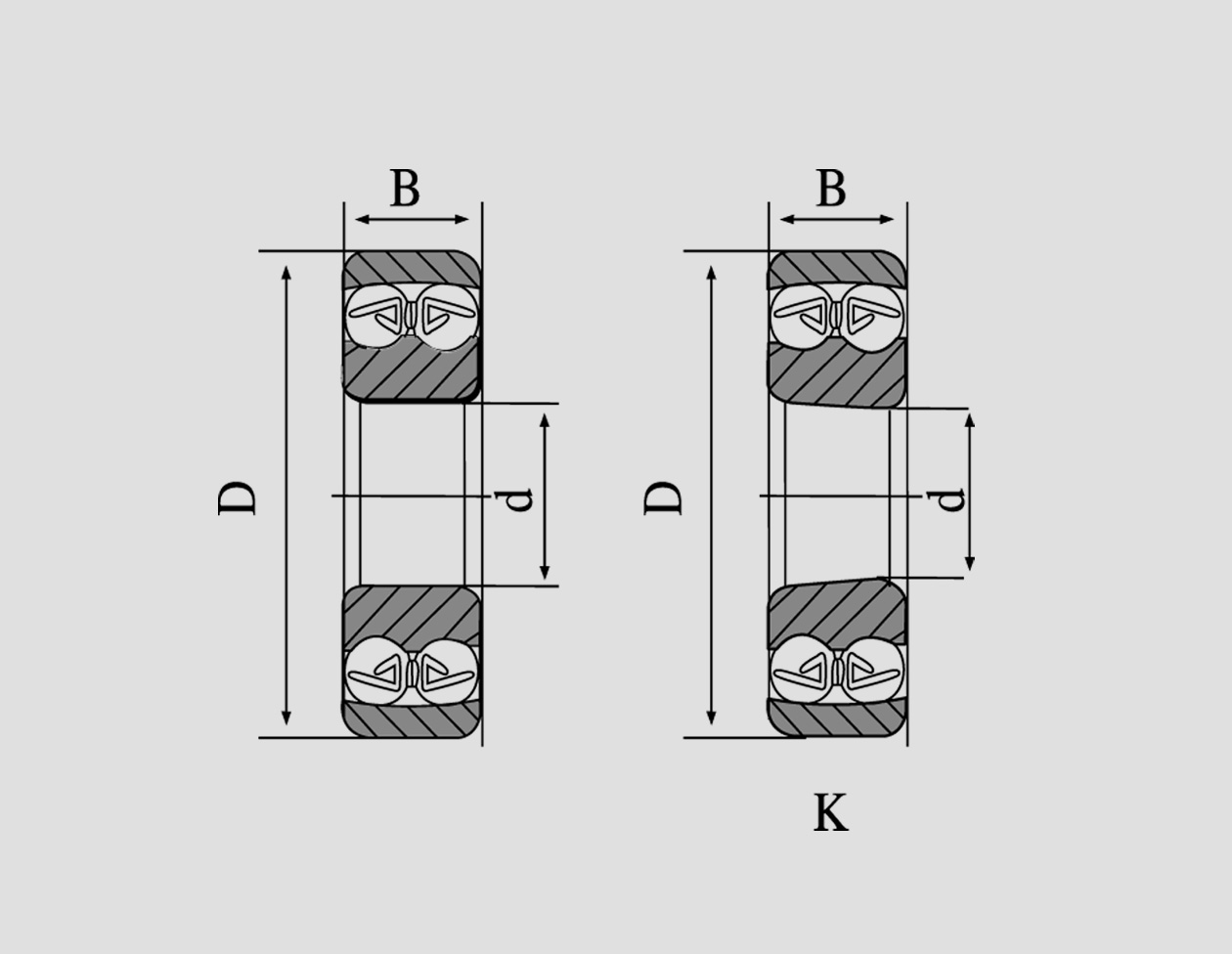

Understanding the dimensions of a ball bearing such as the 6204 is crucial for multiple engineering and mechanical applications. The 6204 ball bearing stands out in a broad spectrum of industries thanks to its balance between efficiency and cost-effectiveness. This article seeks to delve into the specifics of the 6204 dimensions, providing you with the expertise needed when choosing the right bearing for your project.

Beyond these primary dimensions, other factors play significant roles in the performance of a 6204 ball bearing. These include the material composition of the inner and outer races, type of seal or shield, and the presence of any lubrication. Traditionally, these bearings are composed of chrome steel for its excellent hardness and resistance to deformation. However, bearings made from stainless steel or polymer materials are also available for demanding environments where corrosion or magnetic interference might be a concern. Seals and shields are also crucial for the longevity of the bearing. They come in various configurations open, sealed, and shielded. Sealed bearings are designed to prevent the ingress of contaminants such as dirt and moisture, which can significantly degrade performance and lifespan. Shielded versions offer protection against larger particles and are typically used in environments where dust exposure is a concern. Lubrication is another key consideration. Proper lubrication reduces friction, which in turn diminishes heat generation and energy loss. Bearings can be pre-lubricated by the manufacturer with specific grease types that match the speed and load requirements of the application. Ensuring the correct type and quantity of lubrication is paramount to achieving optimal bearing performance. When sourcing 6204 ball bearings, it is advisable to choose suppliers with proven track records and certifications, such as ISO 9001. This ensures that the product meets international quality standards, enhancing reliability and performance. In conclusion, understanding the dimensions and specifications of a 6204 ball bearing is a cornerstone in selecting the right component for your specific needs. Its dimensions - 20mm inner diameter, 47mm outer diameter, and 14mm width - are standardized to facilitate wide applicability in diverse industries. Coupled with considerations around material, seals, and lubrication, this knowledge empowers you to make informed decisions about which bearing will offer the best performance and durability for your application. The well-informed selection not only improves the lifespan of the bearing but also optimizes the operational efficiency of the machinery it supports.

Beyond these primary dimensions, other factors play significant roles in the performance of a 6204 ball bearing. These include the material composition of the inner and outer races, type of seal or shield, and the presence of any lubrication. Traditionally, these bearings are composed of chrome steel for its excellent hardness and resistance to deformation. However, bearings made from stainless steel or polymer materials are also available for demanding environments where corrosion or magnetic interference might be a concern. Seals and shields are also crucial for the longevity of the bearing. They come in various configurations open, sealed, and shielded. Sealed bearings are designed to prevent the ingress of contaminants such as dirt and moisture, which can significantly degrade performance and lifespan. Shielded versions offer protection against larger particles and are typically used in environments where dust exposure is a concern. Lubrication is another key consideration. Proper lubrication reduces friction, which in turn diminishes heat generation and energy loss. Bearings can be pre-lubricated by the manufacturer with specific grease types that match the speed and load requirements of the application. Ensuring the correct type and quantity of lubrication is paramount to achieving optimal bearing performance. When sourcing 6204 ball bearings, it is advisable to choose suppliers with proven track records and certifications, such as ISO 9001. This ensures that the product meets international quality standards, enhancing reliability and performance. In conclusion, understanding the dimensions and specifications of a 6204 ball bearing is a cornerstone in selecting the right component for your specific needs. Its dimensions - 20mm inner diameter, 47mm outer diameter, and 14mm width - are standardized to facilitate wide applicability in diverse industries. Coupled with considerations around material, seals, and lubrication, this knowledge empowers you to make informed decisions about which bearing will offer the best performance and durability for your application. The well-informed selection not only improves the lifespan of the bearing but also optimizes the operational efficiency of the machinery it supports.

Next:

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024