2 月 . 16, 2025 09:04 Back to list

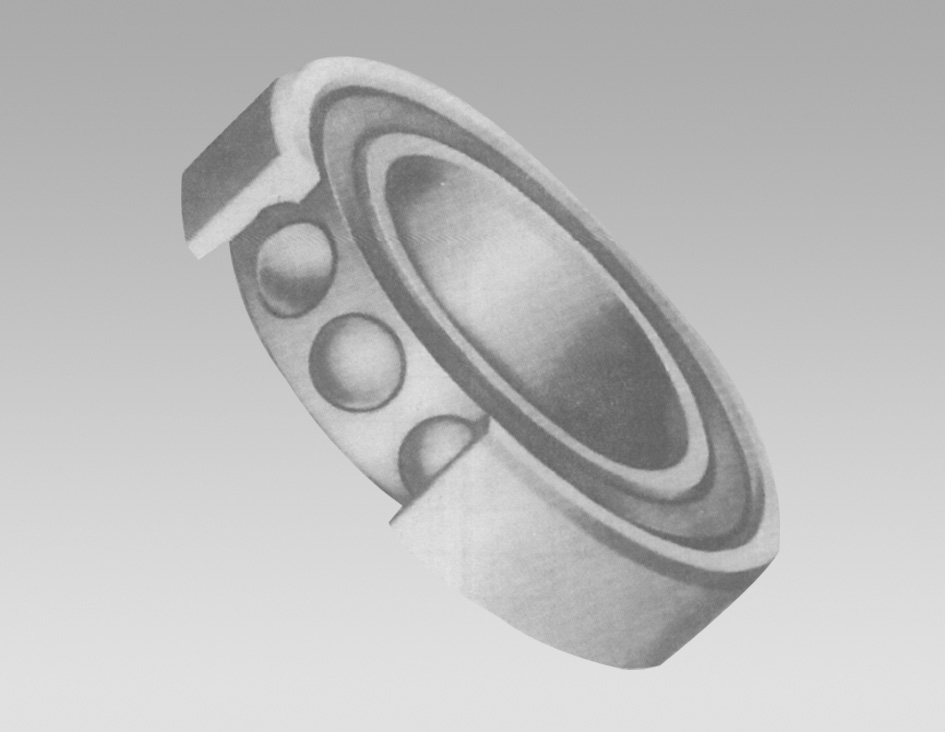

deep groove ball bearing

The popularity and ubiquity of ball bearings underscore their vital role in various machinery and applications. Among them, the 6312 ball bearing stands out as a versatile and reliable component. As we delve into the essential aspects of this bearing, it's crucial to understand why it is a preferred choice for engineers and technicians worldwide.

In terms of maintenance, the 6312 ball bearing is designed for longevity and minimal upkeep. However, routine inspections are advisable to ensure lubrication is adequate and to check for any signs of wear. This proactive approach contributes to their sustained performance and prevents unexpected downtimes, thereby bolstering productivity levels. The expertise involved in the production and selection of the right 6312 ball bearing cannot be overstated. Manufacturers and suppliers with comprehensive experience and knowledge in this field are the preferable choices for procurement. Their understanding of the intricacies involved and capacity to provide tailored solutions enhance the efficiency and reliability of the applications in which these bearings are used. Experience in dealing with ball bearings can be a decisive factor in selecting the appropriate variant for specific needs. Professional guidance based on hands-on experience and a good track record can significantly impact the choice of bearing, ensuring compatibility and performance are aligned with the defined operational requirements. In conclusion, the 6312 ball bearing exemplifies a blend of precision, reliability, and adaptability, making it indispensable in numerous applications. It commands authority in the engineering community due to its superior performance characteristics and has earned a reputation for trustworthiness and expertise. Choosing the right supplier with proven experience in this domain is essential for ensuring that the bearings meet the necessary standards and contribute positively to the functionality of machinery. Such an approach assures that these components remain a pillar in the infrastructure of modern technology, driving efficiency and innovation in a vast array of industries.

In terms of maintenance, the 6312 ball bearing is designed for longevity and minimal upkeep. However, routine inspections are advisable to ensure lubrication is adequate and to check for any signs of wear. This proactive approach contributes to their sustained performance and prevents unexpected downtimes, thereby bolstering productivity levels. The expertise involved in the production and selection of the right 6312 ball bearing cannot be overstated. Manufacturers and suppliers with comprehensive experience and knowledge in this field are the preferable choices for procurement. Their understanding of the intricacies involved and capacity to provide tailored solutions enhance the efficiency and reliability of the applications in which these bearings are used. Experience in dealing with ball bearings can be a decisive factor in selecting the appropriate variant for specific needs. Professional guidance based on hands-on experience and a good track record can significantly impact the choice of bearing, ensuring compatibility and performance are aligned with the defined operational requirements. In conclusion, the 6312 ball bearing exemplifies a blend of precision, reliability, and adaptability, making it indispensable in numerous applications. It commands authority in the engineering community due to its superior performance characteristics and has earned a reputation for trustworthiness and expertise. Choosing the right supplier with proven experience in this domain is essential for ensuring that the bearings meet the necessary standards and contribute positively to the functionality of machinery. Such an approach assures that these components remain a pillar in the infrastructure of modern technology, driving efficiency and innovation in a vast array of industries.

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024