2 月 . 16, 2025 11:37 Back to list

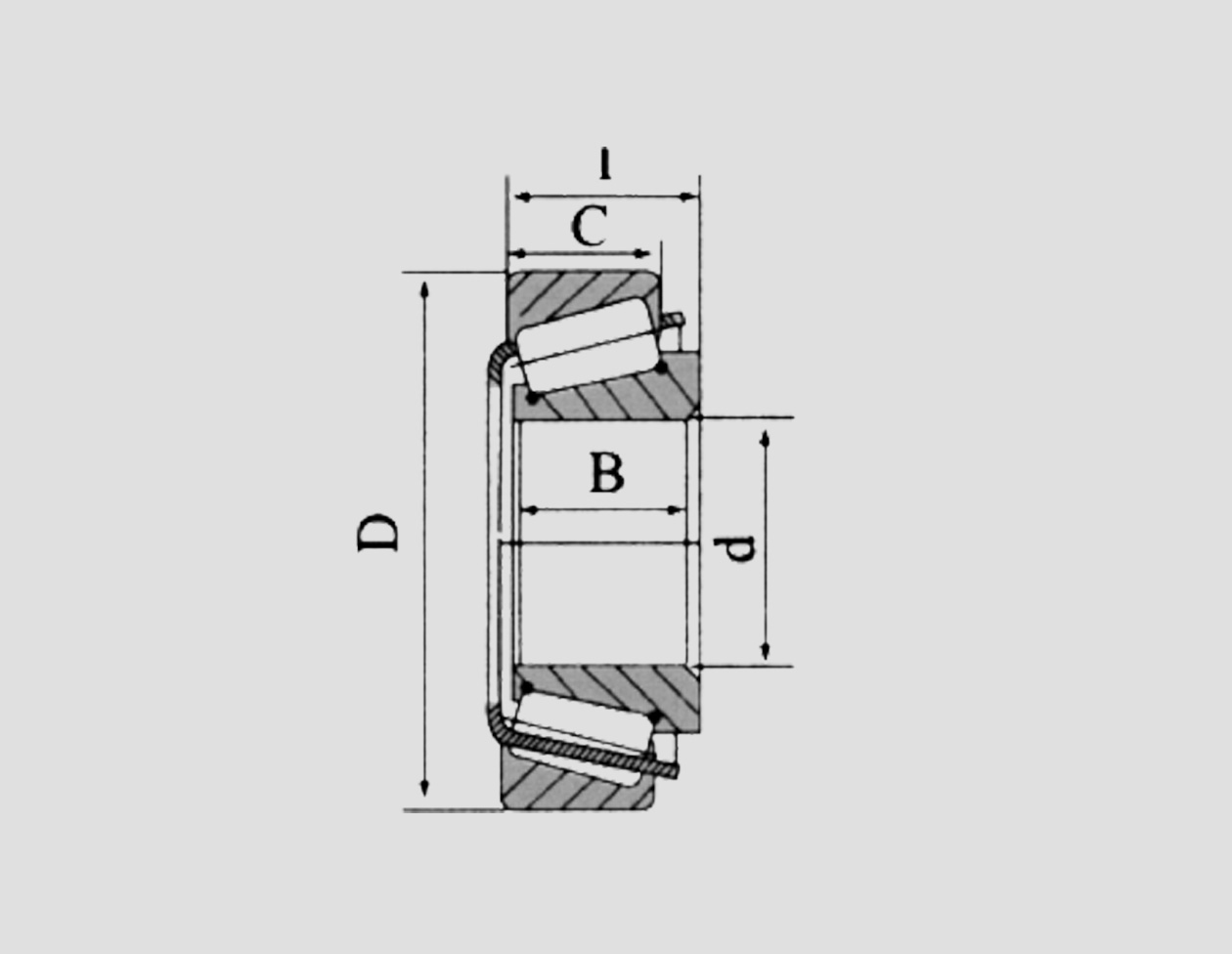

Deep Groove Ball Bearings

Ball groove bearings are pivotal components in various machinery, thanks to their mechanical precision, reliability, and efficiency. Understanding the intricacies of these bearings can significantly enhance their application and maintenance, establishing a strong foundation for higher performance and longevity.

In practice, trustworthiness of ball groove bearings is often gauged by their performance in the field across various industries. For instance, in the automotive sector, these bearings are integral to gearbox operations, where they must withstand substantial stresses and high temperatures. Similarly, in aerospace applications, they contribute to the smooth operation of jet engines, where reliability is non-negotiable. The positive real-world performances reinforce the trust engineers and manufacturers place in these components. Furthermore, maintaining ball groove bearings requires an understanding of their lubrication needs, critical to extending service life and enhancing performance. Proper lubrication reduces wear and heat buildup, which is a primary cause of premature failure. The choice of lubricant—whether grease or oil—depends on the operational environment and bearing material. Regular maintenance checks and adherence to recommended service intervals are essential practices that ensure long-term reliability and performance consistency. In conclusion, ball groove bearings encapsulate a complex interplay of material science, engineering precision, and design innovation. Their pivotal role in reducing friction and enhancing mechanical movement across numerous applications underscores their indispensability in modern machinery. For professionals in fields reliant on these bearings, a comprehensive understanding of their design, materials, and maintenance is essential, ensuring that they consistently deliver outstanding performance while maintaining the machine’s operational integrity. This in-depth expertise and authoritative examination of ball groove bearings reflect the evolving standards and innovations in mechanical engineering. Reliably serving industries worldwide, these bearings are a testament to human ingenuity and technological advancement—a cornerstone of modern mechanical applications.

In practice, trustworthiness of ball groove bearings is often gauged by their performance in the field across various industries. For instance, in the automotive sector, these bearings are integral to gearbox operations, where they must withstand substantial stresses and high temperatures. Similarly, in aerospace applications, they contribute to the smooth operation of jet engines, where reliability is non-negotiable. The positive real-world performances reinforce the trust engineers and manufacturers place in these components. Furthermore, maintaining ball groove bearings requires an understanding of their lubrication needs, critical to extending service life and enhancing performance. Proper lubrication reduces wear and heat buildup, which is a primary cause of premature failure. The choice of lubricant—whether grease or oil—depends on the operational environment and bearing material. Regular maintenance checks and adherence to recommended service intervals are essential practices that ensure long-term reliability and performance consistency. In conclusion, ball groove bearings encapsulate a complex interplay of material science, engineering precision, and design innovation. Their pivotal role in reducing friction and enhancing mechanical movement across numerous applications underscores their indispensability in modern machinery. For professionals in fields reliant on these bearings, a comprehensive understanding of their design, materials, and maintenance is essential, ensuring that they consistently deliver outstanding performance while maintaining the machine’s operational integrity. This in-depth expertise and authoritative examination of ball groove bearings reflect the evolving standards and innovations in mechanical engineering. Reliably serving industries worldwide, these bearings are a testament to human ingenuity and technological advancement—a cornerstone of modern mechanical applications.

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024