10 月 . 15, 2024 12:11 Back to list

Exploring the Historical Significance of Bearing 17887 in Maritime Navigation

Exploring Bearing 17887 A Cornerstone of Engineering

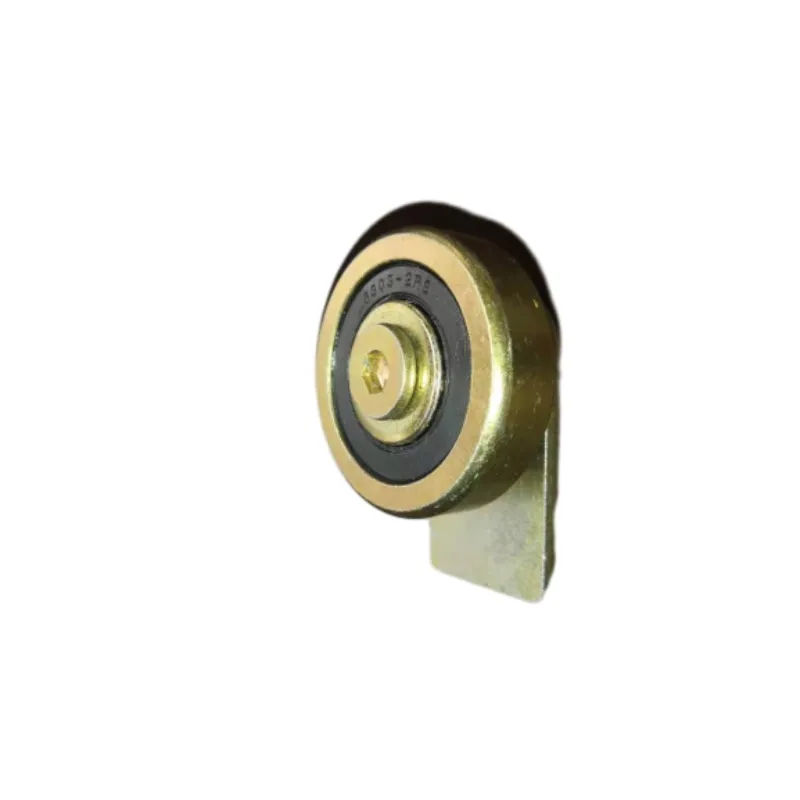

Bearings are fundamental components in a myriad of mechanical systems, serving as crucial elements that facilitate smooth movement and reduce friction between moving parts. Among the vast array of bearings available, Bearing 17887 stands out as a critical player within various industrial applications. This article delves into the characteristics, applications, and importance of Bearing 17887 in the field of engineering.

Exploring Bearing 17887 A Cornerstone of Engineering

In the industrial world, Bearing 17887 can be found in a variety of applications. It's commonly used in automotive, aerospace, manufacturing, and robotics sectors. In automotive applications, for example, bearings play a significant role in wheel hubs, engine components, and transmission systems, ensuring the seamless operation of vehicles. In aerospace, these bearings are integral to the machinery used in aircraft, where precision and reliability are paramount. Manufacturing plants utilize Bearing 17887 in conveyor systems, enabling the efficient movement of goods with reduced wear and tear on parts.

bearing 17887

One of the most significant advantages of Bearing 17887 is its versatility. It can be designed and manufactured to fit specific needs, including variations in size, load capacity, and tolerance levels. This adaptability makes it suitable for a range of machines and systems, from small-scale devices to heavy industrial machinery. Engineers can select the right type of bearing based on the application’s requirements, which helps in optimizing performance and extending the lifespan of the machinery involved.

Furthermore, the importance of proper lubrication cannot be understated when it comes to bearings. Bearing 17887 often operates under conditions that generate significant heat due to friction. Adequate lubrication reduces this heat and minimizes wear on the bearing surfaces. Various types of lubricants can be used, including grease and oil, depending on the specific requirements of the application. Regular maintenance and monitoring are essential to ensure the lubrication remains effective, prolonging the bearing’s life and maintaining its performance.

The innovation surrounding Bearing 17887 and similar components continues to evolve, driven by advancements in materials science and engineering techniques. For instance, the development of advanced ceramic materials has led to the creation of hybrid bearings that can withstand higher speeds and temperatures than traditional steel bearings. Such innovations can significantly enhance the efficiency of machinery, reduce energy consumption, and decrease overall operational costs.

In conclusion, Bearing 17887 exemplifies the critical role that bearings play in engineering and technology. Its robust design, versatility, and efficiency make it indispensable in various applications across multiple industries. As technology continues to advance, the development and refinement of bearings like 17887 ensure that machines operate with optimal performance, enhancing productivity and reliability. Engineers and industries alike must recognize the significance of such components and prioritize their selection, maintenance, and innovation to foster a productive future. The ongoing evolution of bearing technology promises to open new avenues for efficiency and effectiveness in countless applications around the world.

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024