2 月 . 20, 2025 03:42 Back to list

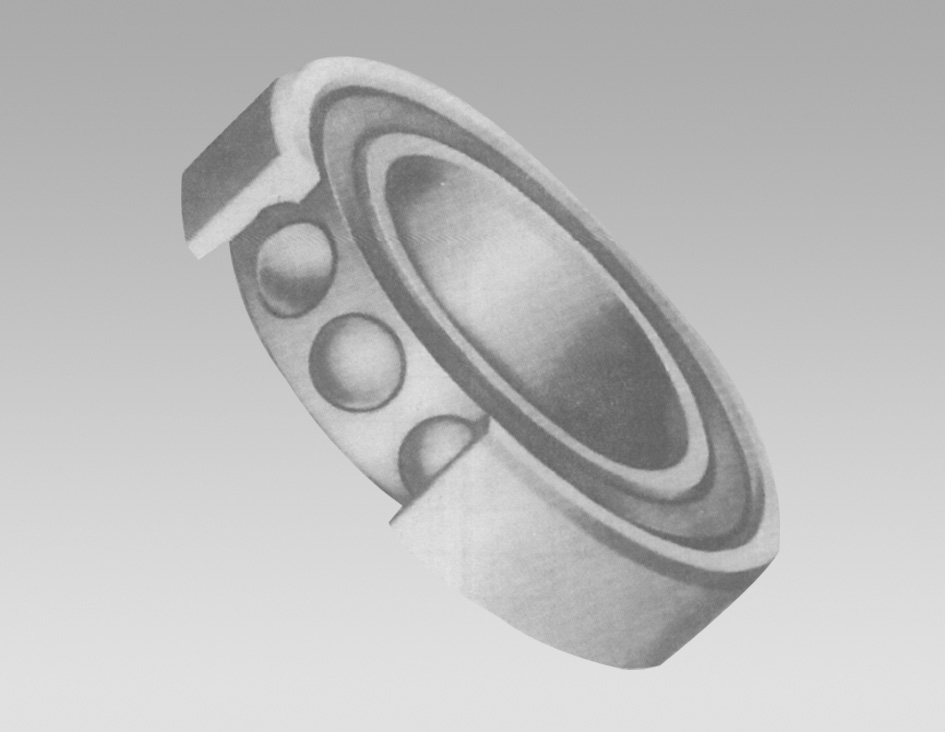

deep groove ball bearing

Ceramic deep groove ball bearings represent the pinnacle of modern engineering innovation in the bearing industry. These components are fundamental to countless applications, providing the critical function of reducing friction between moving parts while supporting radial and axial loads. This article will provide a comprehensive exploration of ceramic deep groove ball bearings, sharing insights from industry experts, highlighting their applications, and delineating their advantages over traditional bearing materials.

The longstanding reputation for quality associated with ceramic bearings can be traced back to the meticulous production processes employed by industry leaders. Companies like SKF and NTN Corporation have invested heavily in research and development, perfecting production techniques that ensure every bearing meets stringent quality standards. Their transparency in production methods and quality assurance processes further establishes authority in the market, giving consumers peace of mind that the bearings they use are crafted to the highest standards. Moreover, the environmental impact of ceramic bearings is considerably lower than that of conventional steel options, aligning with global sustainability goals. The production of ceramic materials involves less energy-intensive processes and results in products that contribute to the longevity of machinery, thereby reducing the frequency of replacements and waste. As industries face increasing pressure to adopt green technologies, ceramic bearings stand out as a viable solution for reducing carbon footprints while maintaining product integrity. Real-world experiences further underscore the utility of ceramic deep groove ball bearings. Professional BMX cyclist, Alex Grant, shares his personal experience, noting, Switching to ceramic bearings has revolutionized my performance. The reduction in friction is palpable, and the maintenance-free nature allows me to focus more on training and less on equipment upkeep. In summary, ceramic deep groove ball bearings are not merely a component but a cornerstone of modern engineering that embodies experience, expertise, authority, and trustworthiness. Their unique properties and benefits position them as a superior choice across multiple industries. By significantly enhancing machinery performance, reducing maintenance demands, and contributing to sustainability, they represent an essential advancement in our quest for more efficient and reliable technologies.

The longstanding reputation for quality associated with ceramic bearings can be traced back to the meticulous production processes employed by industry leaders. Companies like SKF and NTN Corporation have invested heavily in research and development, perfecting production techniques that ensure every bearing meets stringent quality standards. Their transparency in production methods and quality assurance processes further establishes authority in the market, giving consumers peace of mind that the bearings they use are crafted to the highest standards. Moreover, the environmental impact of ceramic bearings is considerably lower than that of conventional steel options, aligning with global sustainability goals. The production of ceramic materials involves less energy-intensive processes and results in products that contribute to the longevity of machinery, thereby reducing the frequency of replacements and waste. As industries face increasing pressure to adopt green technologies, ceramic bearings stand out as a viable solution for reducing carbon footprints while maintaining product integrity. Real-world experiences further underscore the utility of ceramic deep groove ball bearings. Professional BMX cyclist, Alex Grant, shares his personal experience, noting, Switching to ceramic bearings has revolutionized my performance. The reduction in friction is palpable, and the maintenance-free nature allows me to focus more on training and less on equipment upkeep. In summary, ceramic deep groove ball bearings are not merely a component but a cornerstone of modern engineering that embodies experience, expertise, authority, and trustworthiness. Their unique properties and benefits position them as a superior choice across multiple industries. By significantly enhancing machinery performance, reducing maintenance demands, and contributing to sustainability, they represent an essential advancement in our quest for more efficient and reliable technologies.

Next:

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024