9 月 . 28, 2024 18:36 Back to list

Design and Analysis of Conical Thrust Bearings for Enhanced Load Capacity and Performance

Understanding Conical Thrust Bearings An Overview

Conical thrust bearings are a specific class of bearings designed to support axial loads while allowing for rotational motion. With their unique structure, these bearings provide a robust solution in various applications, from automotive to heavy machinery. This article delves into the design, function, advantages, and applications of conical thrust bearings.

Design and Structure

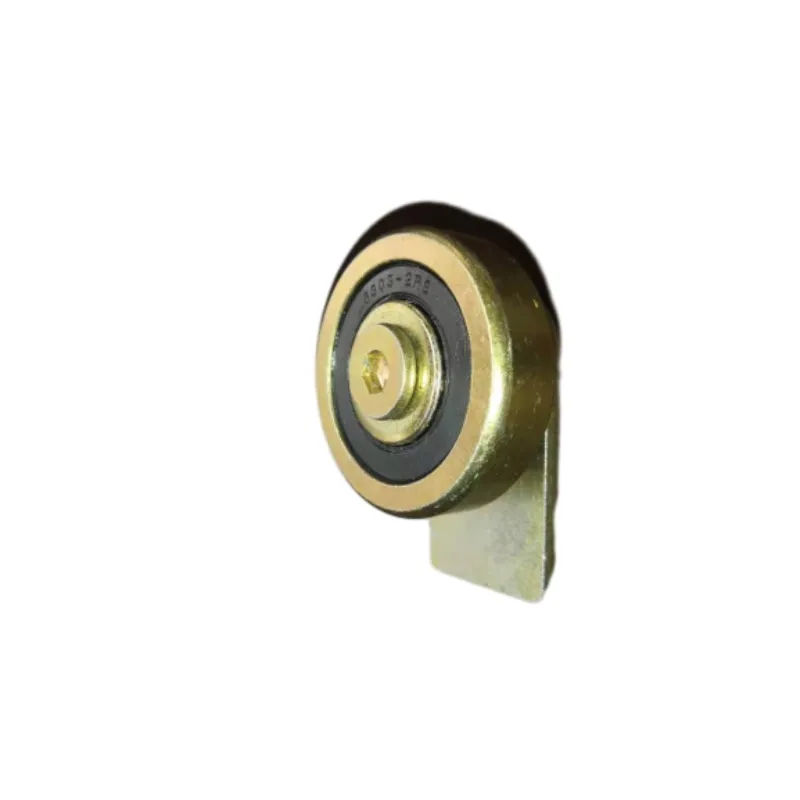

Conical thrust bearings consist of an outer race, an inner race, and a set of tapered rolling elements, typically composed of steel or other high-strength materials. The conical shape of the rolling elements allows them to accommodate axial loads effectively. The arrangement of these elements creates a cornering effect, which enhances the load-bearing capacity and stability of the bearing system.

The bearing operates on the principle of rolling friction, where the tapered rollers roll along the inclined surfaces of the inner and outer races. This configuration reduces wear and heat generation during operation, promoting longevity and reliability. Typically, conical thrust bearings are housed in various configurations, including single-row and multi-row setups, depending on the load requirements of the application.

Functionality

The primary function of a conical thrust bearing is to support axial loads while enabling smooth rotational movement. This is crucial in applications where shafts rotate and require precise positioning or alignment. The tapered design allows the load to be distributed across a broader surface area, reducing the risk of localized stress concentrations that can lead to failure.

These bearings also accommodate slight angular misalignments, making them ideal in scenarios where components may not be perfectly aligned. This feature is particularly beneficial in automotive applications, where engine vibrations and movements can lead to misalignments over time.

Advantages of Conical Thrust Bearings

conical thrust bearing

1. Increased Load Capacity The tapered design allows for higher axial load capacities compared to radial bearings. This feature is vital in heavy machinery and high-performance applications.

2. Enhanced Durability With reduced friction and efficient load distribution, conical thrust bearings have lower wear rates, leading to longer service life and reduced maintenance costs.

3. Versatility Conical thrust bearings can be used in a variety of environments and conditions, making them suitable for numerous applications across different industries.

4. Reduced Heat Generation The rolling motion of the tapered elements minimizes heat generation during operation, preventing overheating and potential damage to the bearing and adjacent components.

Applications

Conical thrust bearings are widely employed in several industries due to their excellent performance characteristics. Some notable applications include

- Automotive Used in the gearbox and differential systems, facilitating smooth operation under heavy loads. - Aerospace Employed in various aircraft systems, where precise axial load handling is critical for safety and performance. - Heavy Machinery Found in construction equipment, such as excavators and cranes, where they support significant axial loads while enabling rotation. - Power Generation Utilized in turbines and generators, where controlled rotational motion and load handling are essential.

Conclusion

Conical thrust bearings play a crucial role in modern engineering by providing efficient solutions for axial load handling and rotational motion. Their unique design offers numerous advantages, including enhanced load capacity, durability, and versatility, making them indispensable across various industries. As technology continues to evolve, the importance of advanced bearing systems like conical thrust bearings will only increase, ensuring that machines and equipment operate reliably and efficiently in an ever-demanding world.

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024