11 月 . 01, 2024 08:43 Back to list

Understanding Deep Groove Ball Bearings for Various Applications and Their Benefits

Understanding Deep Groove Ball Bearings A Comprehensive Overview

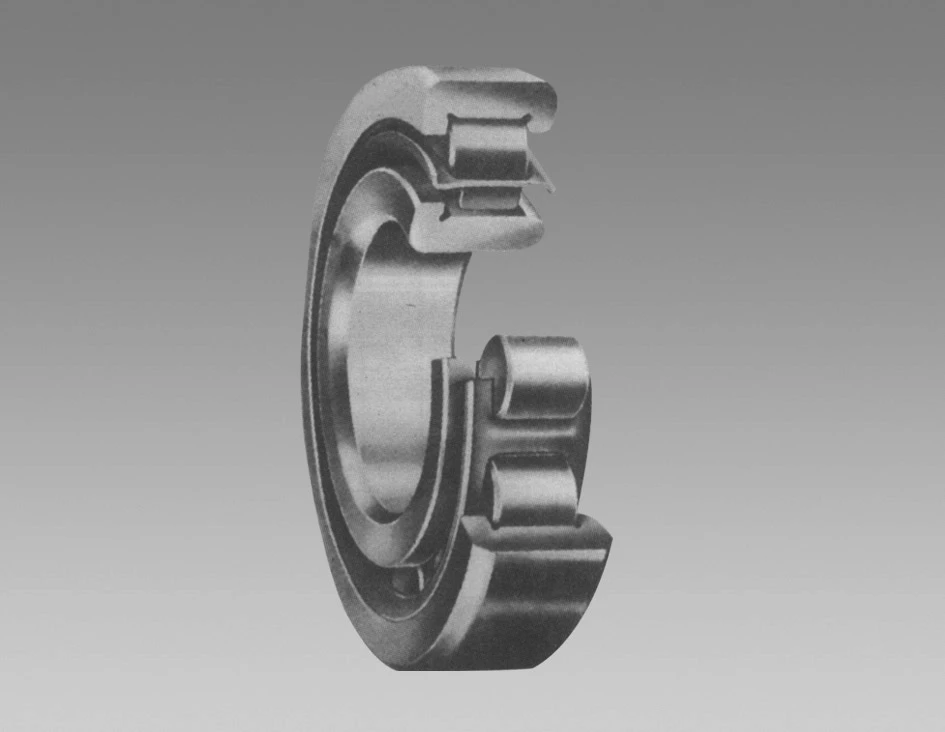

Deep groove ball bearings are among the most widely used types of bearings in various applications due to their versatility, simplicity, and effectiveness. Characterized by their deep raceway grooves, these bearings can accommodate both radial and axial loads, making them suitable for a wide range of operational conditions.

One of the defining features of deep groove ball bearings is their design. They consist of an inner ring, an outer ring, a cage, and a set of balls. The deep grooves allow the balls to stay in place even under heavy loads, contributing to the bearing's durability and reliability. This design enables the bearing to perform efficiently at high speeds, making them ideal for applications in electric motors, household appliances, automotive components, and more.

Understanding Deep Groove Ball Bearings A Comprehensive Overview

Deep groove ball bearings come in various sizes and configurations, including open, sealed, and shielded variants. Open bearings are designed for applications where lubrication is readily available, while sealed and shielded types provide protection against contaminants and help retain lubrication, making them suitable for environments where dust and moisture might be present.

deep groove ball bearing pdf

Another notable aspect of deep groove ball bearings is their load capacity. They can carry substantial radial loads and a significant amount of axial loads in both directions. This dual load-carrying capability sets them apart from other types of bearings, allowing for more versatile use in machinery and equipment.

Furthermore, the manufacturing quality of deep groove ball bearings is critical to their performance. High-quality materials, precise manufacturing processes, and stringent quality control measures are essential to produce bearings that can withstand operational stresses and friction. Innovations in materials, such as the introduction of ceramic balls and advanced steel alloys, have further enhanced the performance characteristics of these bearings, making them suitable for high-temperature and high-speed applications.

Maintenance is another key aspect of ensuring the longevity of deep groove ball bearings. Regular inspections, proper lubrication, and timely replacement will help prevent premature failure and maintain optimal performance. With advancements in technology, some modern bearings feature lubrication that can last for the lifetime of the bearing, reducing the need for frequent maintenance.

In conclusion, deep groove ball bearings are fundamental components in a variety of mechanical systems. Their unique design allows them to support both radial and axial loads while maintaining high performance under various conditions. With their durability, versatility, and ease of maintenance, deep groove ball bearings continue to play a vital role in the advancement of machinery and technology across numerous industries. Understanding their features and applications can lead to better choices and innovations in bearing design and usage.

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024