1 月 . 16, 2025 05:26 Back to list

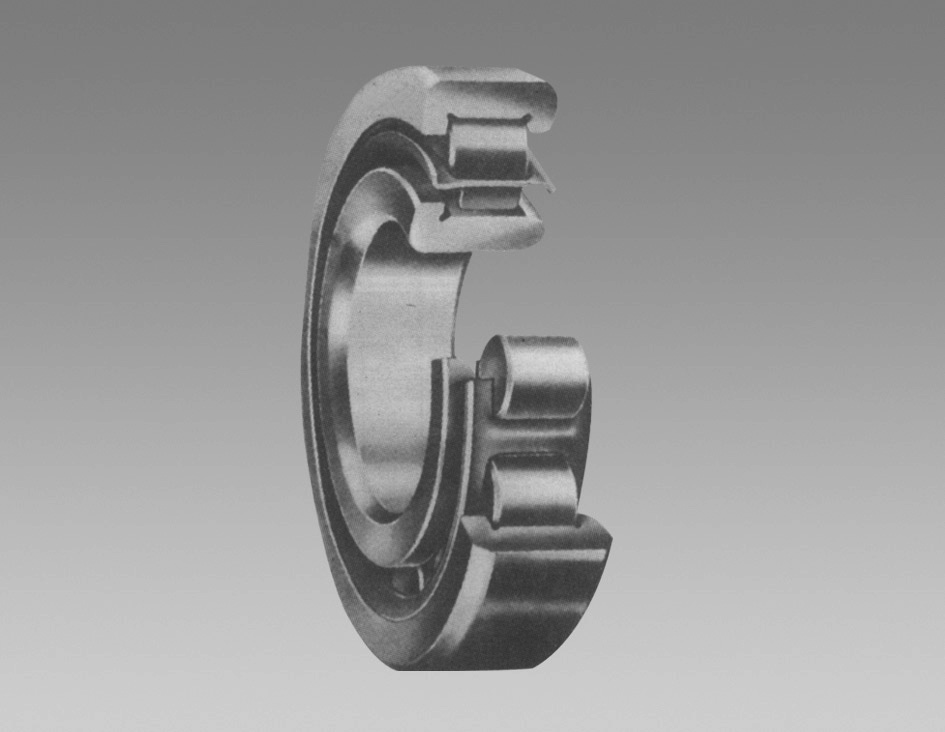

Deep Groove Ball Bearing

Deep groove ball bearings are fundamental components in various industrial applications, renowned for their versatility and durability. Engineers and industry professionals often rely on these bearings due to their capacity to accommodate both radial and axial loads, making them indispensable in numerous machinery and equipment. When looking into the specifications of deep groove ball bearings, it's crucial to understand their detailed attributes to ensure optimal performance.

The lubrication method is another specification that can't be overlooked. Proper lubrication minimizes friction and wear, significantly extending the bearing's life. Pre-lubricated bearings are a common choice for their ease of use, while those requiring external lubrication might be preferred in high-temperature applications where specific greases can withstand greater thermal challenges. Bearings also vary in precision grades, which are vital in applications demanding high accuracy and minimal vibration, such as aerospace or precision machinery. Higher precision grades ensure smoother operation, reduced noise, and enhanced efficiency, albeit often at a higher cost. One must not overlook the mounting and maintenance requirements specified by manufacturers. Proper installation is crucial as improper alignment or excessive force during installation can lead to premature failure. Maintenance schedules predicated on operation conditions further guarantee sustained performance, helping to preempt costly downtimes and repairs. When selecting deep groove ball bearings, working with reliable manufacturers who adhere to international standards like ISO 9001 ensures a level of trustworthiness and quality assurance. Experienced manufacturers provide comprehensive data sheets and technical support to aid in the proper selection and maintenance of the bearings, aligning with best practices in engineering fields. Ultimately, understanding these specifications not only aligns with the technical demands of the application but also supports improved efficiency and reliability, underscoring the essential role that deep groove ball bearings play in modern engineering solutions. By choosing the right specifications, industries can enhance machinery performance, reduce maintenance costs, and increase the overall productivity of their operations.

The lubrication method is another specification that can't be overlooked. Proper lubrication minimizes friction and wear, significantly extending the bearing's life. Pre-lubricated bearings are a common choice for their ease of use, while those requiring external lubrication might be preferred in high-temperature applications where specific greases can withstand greater thermal challenges. Bearings also vary in precision grades, which are vital in applications demanding high accuracy and minimal vibration, such as aerospace or precision machinery. Higher precision grades ensure smoother operation, reduced noise, and enhanced efficiency, albeit often at a higher cost. One must not overlook the mounting and maintenance requirements specified by manufacturers. Proper installation is crucial as improper alignment or excessive force during installation can lead to premature failure. Maintenance schedules predicated on operation conditions further guarantee sustained performance, helping to preempt costly downtimes and repairs. When selecting deep groove ball bearings, working with reliable manufacturers who adhere to international standards like ISO 9001 ensures a level of trustworthiness and quality assurance. Experienced manufacturers provide comprehensive data sheets and technical support to aid in the proper selection and maintenance of the bearings, aligning with best practices in engineering fields. Ultimately, understanding these specifications not only aligns with the technical demands of the application but also supports improved efficiency and reliability, underscoring the essential role that deep groove ball bearings play in modern engineering solutions. By choosing the right specifications, industries can enhance machinery performance, reduce maintenance costs, and increase the overall productivity of their operations.

Next:

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024