8 月 . 16, 2024 23:58 Back to list

Design and Applications of Single Thrust Ball Bearings in Machinery Systems

Understanding Single Thrust Ball Bearings

Single thrust ball bearings are crucial components in various mechanical systems, providing efficiency and reliability. These bearings are designed specifically to accommodate axial loads in one direction, making them ideal for applications where rotational movement is required with minimal friction. This article delves into the design, function, applications, and maintenance of single thrust ball bearings, highlighting their significance in engineering and machinery.

Design and Structure

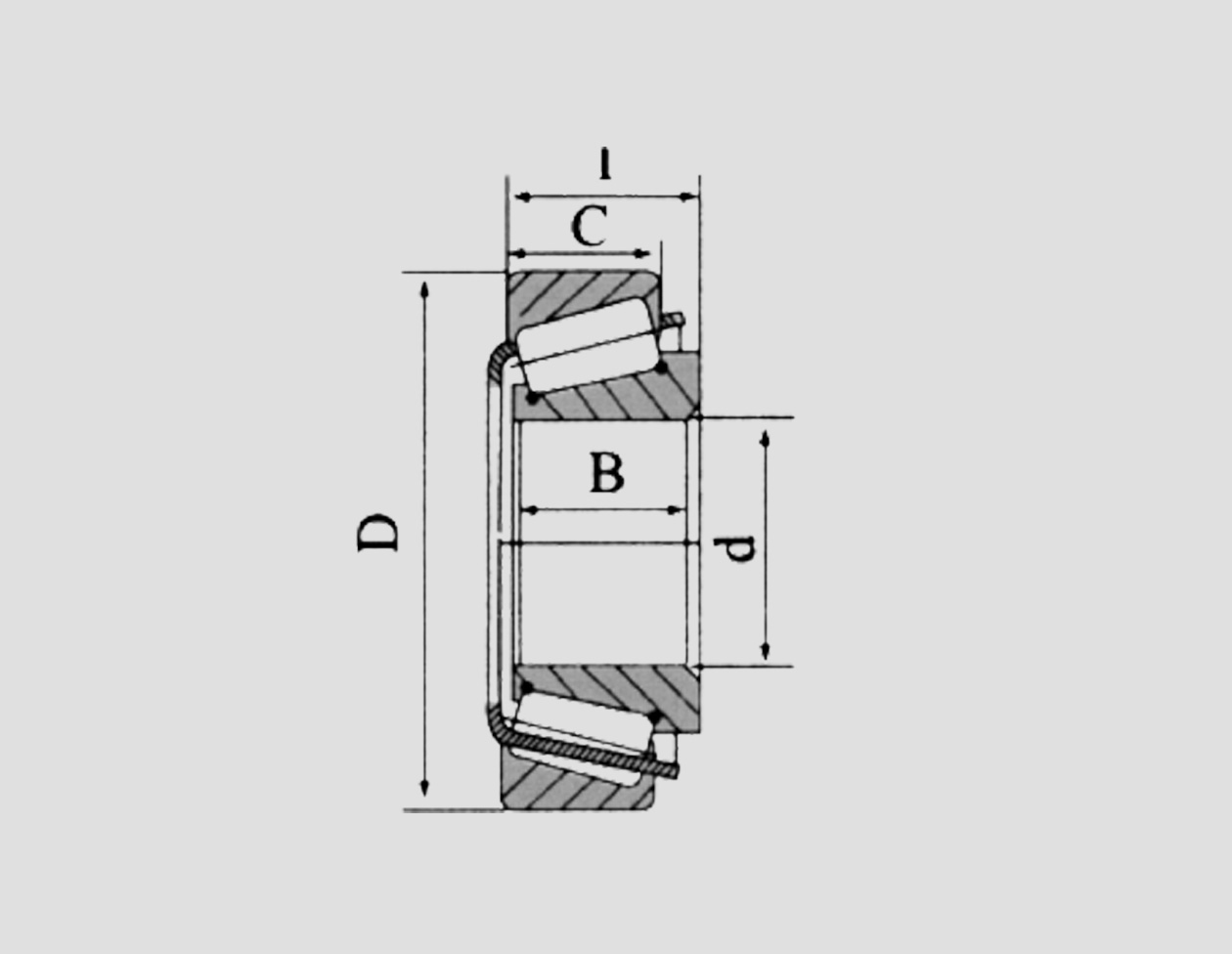

A single thrust ball bearing consists of a ball, a raceway, and a housing. The design primarily includes a set of balls positioned within a raceway, allowing for smooth rolling motion. The bearing is constructed to support axial loads, which are forces acting along the axis of the shaft. The internal layout ensures that the balls roll along the grooves of the raceway, providing reduced friction compared to sliding surfaces. Moreover, thrust ball bearings typically feature a separation between the balls which prevents them from rubbing against each other.

The materials used for these bearings are usually high-grade steel or other alloys that can withstand wear and tear. The outer and inner rings are precision-engineered to support the required load and reduce the risk of failure under operational conditions. The precision in the manufacturing process ensures that the bearings deliver reliable performance over extended periods.

Functionality

Single thrust ball bearings function by allowing rotation between the stationary and moving parts of machinery while supporting axial loads. These bearings can handle thrust loads, which makes them particularly suitable for applications where one part must push against another, such as in gearboxes or clutches. The capability to handle a specific range of load capacities makes them versatile across various sectors.

One of the critical advantages of thrust ball bearings is their ability to accommodate misalignment between shaft and housing. They can operate effectively even when there is slight misalignment, which can occur due to manufacturing tolerances or wear over time.

single thrust ball bearing

Applications

Single thrust ball bearings are employed in numerous applications across different industries. They are commonly found in automotive applications—such as in transmissions and drive shafts—where they help manage the thrust loads generated during operation. Additionally, these bearings are often used in industrial machinery, including conveyor systems and heavy equipment. Their ability to withstand axial loads with reduced friction makes them integral to maintaining efficiency in power transmission systems.

In the aviation sector, thrust bearings play a crucial role in the engines and landing gear systems, where managing forces effectively is vital to safety and performance. Furthermore, they find usage in household appliances like washing machines, where they help in managing the forces generated during cycles.

Maintenance and Care

To ensure the longevity and performance of single thrust ball bearings, regular maintenance is essential. Proper lubrication is crucial to minimize friction and wear. The type of lubricant used should align with the operating conditions, including temperature and load.

Moreover, regular inspections for signs of wear, debris accumulation, or misalignment can prevent failures. Bearings should be replaced promptly if any signs of distress are observed, as neglect can lead to complete operational failures and costly downtimes.

In conclusion, single thrust ball bearings are vital components in various mechanical systems, designed to support axial loads efficiently. Their unique design and functionality make them indispensable in numerous industrial and automotive applications, ensuring smooth and reliable operation. Understanding their importance and maintaining them properly can significantly enhance machinery performance and longevity.

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024