11 月 . 01, 2024 12:40 Back to list

Understanding the Four Main Categories of Roller Bearings and Their Applications

The Four Types of Roller Bearings

Roller bearings are essential components in various machinery, enabling smooth rotation and reducing friction between moving parts. They come in several types, each designed for specific applications and load conditions. In this article, we will explore four common types of roller bearings cylindrical, spherical, tapered, and needle roller bearings.

1. Cylindrical Roller Bearings

Cylindrical roller bearings feature cylindrical rollers that provide a large contact surface with the races, allowing them to handle heavy radial loads. This type of bearing is well-suited for high-speed applications because of its ability to distribute loads evenly across the rollers, minimizing stress and wear. They are available in several designs, including single-row, double-row, and even multi-row configurations. Common applications for cylindrical roller bearings include electric motors, pumps, and gearboxes, where reliable and efficient load handling is critical.

Spherical roller bearings are designed to accommodate misalignment and angular misalignment between the shaft and housing. Their unique design features an inner ring with two rows of symmetrical rollers set within a spherical outer ring. This configuration allows the bearing to self-align, making it suitable for rotor applications in electric machines and other heavy-duty operations. Spherical roller bearings can support both radial and axial loads, making them versatile choices for applications such as mining, construction, and heavy machinery.

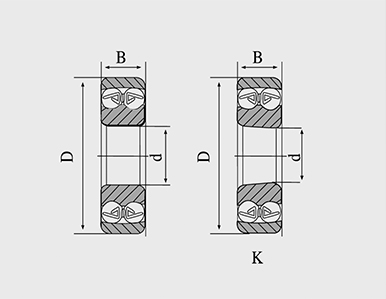

four types of roller bearings

3. Tapered Roller Bearings

Tapered roller bearings have tapered rollers that create a line contact with the raceways, allowing them to handle both radial and axial loads effectively. This design enables them to support significant loads when properly aligned. Tapered roller bearings are often used in applications where thrust loads are present, such as in automotive wheel hubs and gear drives. They come in various designs, including single-row, double-row, and four-row configurations, catering to specific load and speed requirements. Their ability to withstand high loads and provide desired rigidity makes them a popular choice in many industries.

4. Needle Roller Bearings

Needle roller bearings are characterized by their elongated rollers, which are smaller in diameter compared to other roller types. Despite their size, needle roller bearings can support high radial loads due to their large contact area. They are particularly effective in compact spaces, making them ideal for applications where space is limited, such as in automotive transmissions and various small machines. Needle roller bearings can also come in mixed types, allowing them to handle axial loads along with radial loads efficiently.

Conclusion

Each type of roller bearing offers unique advantages tailored to specific mechanical needs. Cylindrical roller bearings are ideal for high-speed applications; spherical roller bearings excel in misalignment situations; tapered roller bearings are designed for both axial and radial loads; and needle roller bearings provide solutions in compact spaces. Understanding these types aids engineers and designers in selecting the most suitable bearings for their applications, enhancing reliability and performance in machinery. With advancements in bearing technology continually evolving, the future of roller bearings holds promise for even more innovative design solutions.

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024