10 月 . 02, 2024 18:05 Back to list

High-Performance Deep Groove Ball Bearings for Elevated Temperature Applications

High Temperature Deep Groove Ball Bearings The Ultimate Solution for Extreme Conditions

In industrial applications, equipment reliability and longevity are paramount. One of the key components contributing to the efficiency and durability of machinery is the bearing system. Among the various types of bearings available, high temperature deep groove ball bearings stand out as an exceptional solution for environments exposed to elevated temperatures.

Understanding Deep Groove Ball Bearings

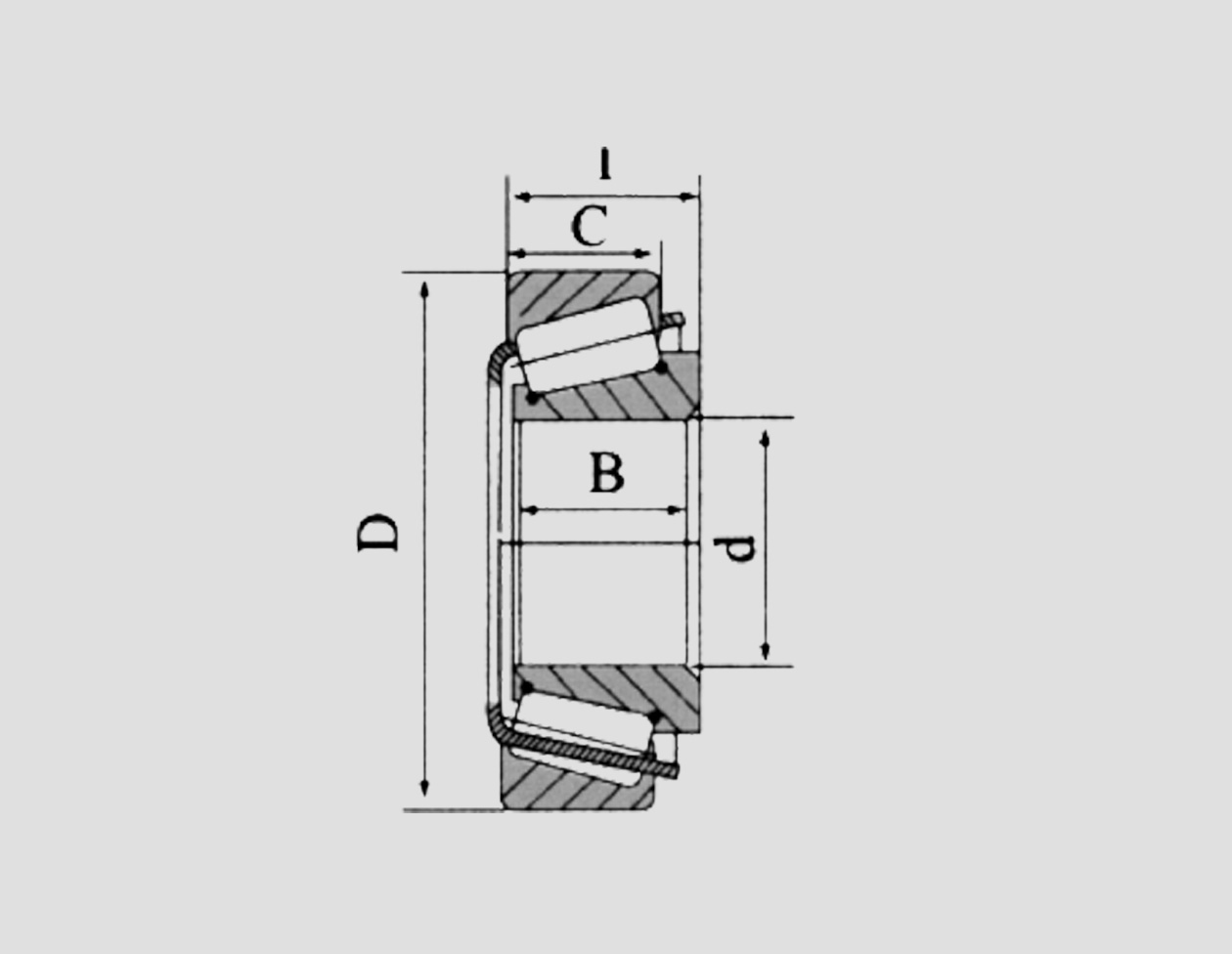

Deep groove ball bearings are one of the most common types of rolling bearings. They consist of an inner ring, an outer ring, and a set of balls between the two rings. This design allows for smooth operation at high speeds and the ability to accommodate both radial and axial loads, making them versatile for various applications.

However, standard deep groove ball bearings can struggle under high-temperature conditions, leading to premature failure. This is where high temperature variants come into play.

Characteristics of High Temperature Deep Groove Ball Bearings

High temperature deep groove ball bearings are specifically engineered to withstand elevated heat conditions, typically exceeding 100°C (212°F) and, in some cases, reaching up to 200°C (392°F) or higher

. These bearings are constructed using specialized heat-resistant materials and lubricants that ensure optimal performance and reliability even under thermal stress.1. Material Composition High temperature bearings are often made from materials such as stainless steel, ceramics, or specially treated steels that maintain their structural integrity at high temperatures. This prevents deformation and deterioration, prolonging the bearing's lifespan.

high temperature deep groove ball bearing

2. High-Performance Lubricants The lubricants used in these bearings are formulated to maintain viscosity and reduce friction at elevated temperatures. This is crucial as traditional lubricants may break down or lose effectiveness, leading to metal-to-metal contact and increased wear.

3. Sealing and Shielding Good sealing is vital in high-temperature applications, as contaminants can exacerbate wear. High temperature deep groove ball bearings often feature advanced sealing technologies to protect against dust, moisture, and other harmful substances while maintaining lubrication.

Applications of High Temperature Deep Groove Ball Bearings

These bearings find widespread use in industries and applications where operating conditions can reach high temperatures. Common applications include

- Electric Motors In electric motors, especially those used in high-temperature environments like furnaces or incinerators, reliable bearings are essential for maintaining efficiency and performance. - Manufacturing Equipment During processes that involve excessive heat, such as metal forging and casting, high temperature bearings ensure that machinery runs smoothly without interruptions. - Textile Machinery Textile production often involves high-temperature processes, especially in dyeing and finishing stages. High temperature bearings help in maintaining production efficiency. - Automotive Sector Components such as turbochargers and exhaust systems generate significant heat; high temperature bearings are used to ensure these systems function correctly.

Conclusion

High temperature deep groove ball bearings represent a critical advancement in bearing technology, allowing industries to meet the demands of extreme conditions without compromising performance. With their robust construction, specialized materials, and innovative lubricants, these bearings enable machinery to operate efficiently while minimizing shutdowns due to bearing failures. As industries continue to push the limits of temperature and performance, the importance of high temperature deep groove ball bearings will only grow, paving the way for more reliable and efficient industrial processes. Investing in quality bearings is not just about immediate performance; it's about ensuring the long-term success and efficiency of operations across various applications.

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024