1 月 . 06, 2025 19:44 Back to list

Enhance Performance with High-Quality Machinery Bearings

Machinery bearings are indispensable components in virtually every industrial sector, acting as the backbone for smooth mechanical operations. From automotive to aerospace, their application is widespread, demonstrating their unparalleled significance. Manufacturers across the globe rely heavily on these components to ensure machines operate efficiently, reduce energy consumption, and extend operational lifespan.

Understanding the nuances of machinery bearings is crucial for optimal performance. Bearings, by their design, provide precision in motion, translating rotational or linear movements with minimal friction. This essentially enables machines to operate at increased efficiency levels, thus conserving energy and reducing wear and tear—a significant advantage in industries where machinery operates nonstop.

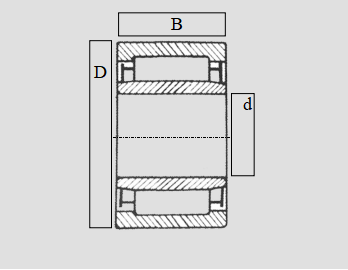

To truly appreciate the importance of bearings, one must delve into the sophisticated engineering that underpins their design and function. Bearings are not a one-size-fits-all component. They come in various types ball bearings, roller bearings, needle bearings, and more, each crafted meticulously to serve specific functions and cater to diverse load demands. The expertise in selecting the right type of bearing is pivotal. For instance, ball bearings are typically employed in applications requiring low friction and high-speed capabilities, whereas roller bearings are designed to handle heavier loads efficiently.

Authoritative insight into machinery bearings also involves understanding the materials used in their construction. Typically composed of steel, ceramics, or polymers, each material offers distinct benefits. For instance, ceramics provide unmatched resistance to heat and wear, making them ideal for high-temperature applications. Polymers, on the other hand, offer corrosion resistance and are often used in environments where bearings might be exposed to chemicals or moisture. The choice of material significantly impacts the bearing’s performance, durability, and suitability for specific environments.

machinery bearings

The trustworthiness of bearing performance is often validated by rigorous testing and adherence to internationally recognized standards. Renowned manufacturers conduct extensive tests to evaluate factors such as load capacity, lifespan, and efficiency under various operational conditions. Certifications from organizations such as the International Organization for Standardization (ISO) underscore a manufacturer’s commitment to quality, safety, and environmental management practices. These certifications not only enhance the credibility of the products but also instill confidence among users about the bearings’ reliability and safety.

Incorporating real-world experience is another vital aspect. Industrial operators often share valuable insights about bearing performance in specific applications. For example, in the food processing industry, where hygiene is paramount, bearings with self-lubricating properties or those made from stainless steel are preferred to minimize contamination risk and ensure operational efficiency. In such settings, user feedback is instrumental in refining product offerings and innovating new solutions.

The future of machinery bearings aligns with technological advancements, notably in smart manufacturing. The integration of sensors within bearings is revolutionizing predictive maintenance. These sensors provide real-time data on bearing health, enabling timely interventions before critical failures occur. This not only minimizes downtime but also maximizes the operational lifespan of machinery, offering substantial cost savings in the long run.

In conclusion, machinery bearings may appear inconspicuous at first glance, but their role in industrial applications is profound and multifaceted. By leveraging expertise in material selection, type of bearing, and real-world applications, businesses can enhance machine performance and reliability. Trusted manufacturers that adhere to stringent quality standards and continuously innovate their offerings are pivotal partners in any industrial venture. As industries evolve, the significance of machinery bearings only magnifies, underscoring their role as essential enablers of operational efficiency and effectiveness.

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024