10 月 . 22, 2024 14:22 Back to list

sealed angular contact bearings

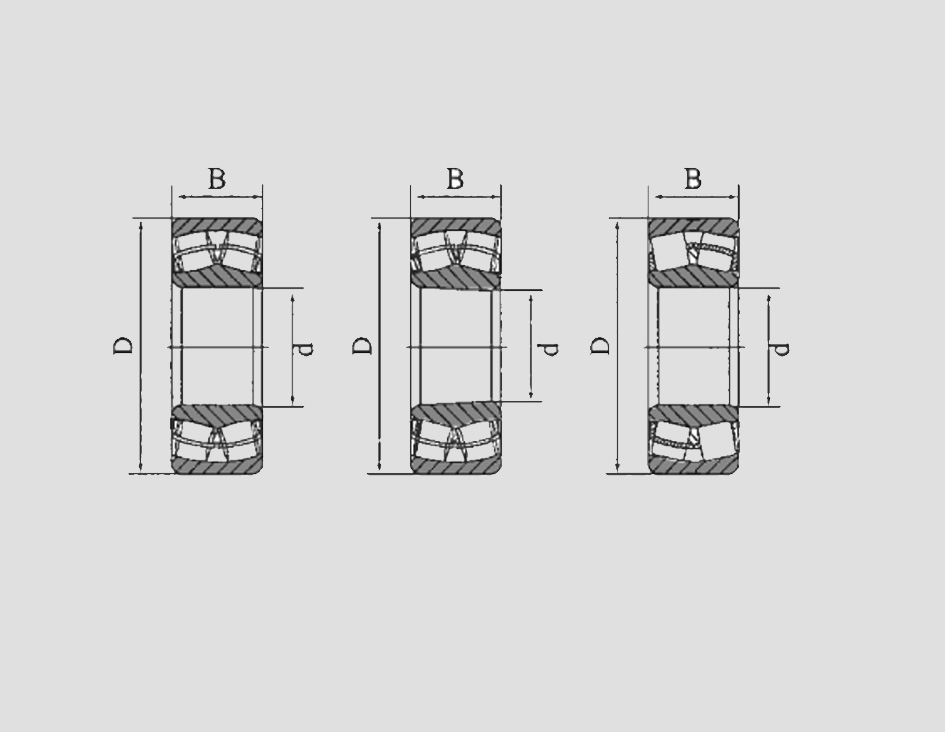

Sealed Angular Contact Bearings A Comprehensive Overview

Sealed angular contact bearings play a critical role in various mechanical applications, ensuring high precision and efficiency in performance. Unlike traditional bearings, sealed angular contact bearings are designed with a unique geometry and sealing arrangements that provide superior protection against contaminants. This article delves into the characteristics, advantages, and applications of these specialized bearings.

Characteristics of Sealed Angular Contact Bearings

Angular contact bearings are structured to accommodate axial loads in one direction while allowing for radial loads. This capability is primarily achieved through their integrated contact angle, which varies depending on the design—typically between 15 to 40 degrees. The term sealed indicates that these bearings are equipped with seals on both sides, offering a robust barrier against dust, dirt, and moisture. This feature is particularly beneficial in environments prone to contamination, extending the bearing's lifespan and maintaining operational integrity.

These bearings are manufactured using high-grade materials, often comprising precision steel or ceramic. The inner and outer raceways are expertly machined to reduce friction, allowing for high-speed operation. Additionally, sealed angular contact bearings come in various sizes and configurations, enabling them to meet specific application requirements.

Advantages of Sealed Angular Contact Bearings

sealed angular contact bearings

One of the most significant advantages of sealed angular contact bearings is their enhanced protection against external elements. The seals prevent contaminants from penetrating the bearing, which is critical in maintaining lubrication. As a result, these bearings can operate at higher speeds and under heavier loads than their unsealed counterparts. The reduced risk of wear and damage leads to lower maintenance costs and minimized downtime, making them a cost-effective choice in the long run.

Another benefit is their improved performance in harsh conditions, such as high temperatures or environments with aggressive chemicals. The ability to withstand these factors while remaining reliable is crucial for sectors like aerospace, machine tools, and automotive applications, where precision and durability are paramount.

Applications of Sealed Angular Contact Bearings

Sealed angular contact bearings find versatile applications across various industries. In the automotive sector, they are used in wheel hubs, where they support both axial and radial loads while ensuring smooth rotation. In robotics and automation, these bearings facilitate precise movement and positioning, which is essential for operational accuracy.

Moreover, in manufacturing, they are widely employed in CNC machines and other high-speed equipment. Their reliability and performance under load make them suitable for critical applications, where failure is not an option.

In conclusion, sealed angular contact bearings are an essential component of modern machinery. Their unique design, coupled with enhanced protection against contaminants, offers significant advantages in many industrial applications. As technology continues to advance, the role of these bearings will undoubtedly expand, further underscoring their importance in ensuring operational efficiency and reliability.

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024