2 月 . 19, 2025 07:36 Back to list

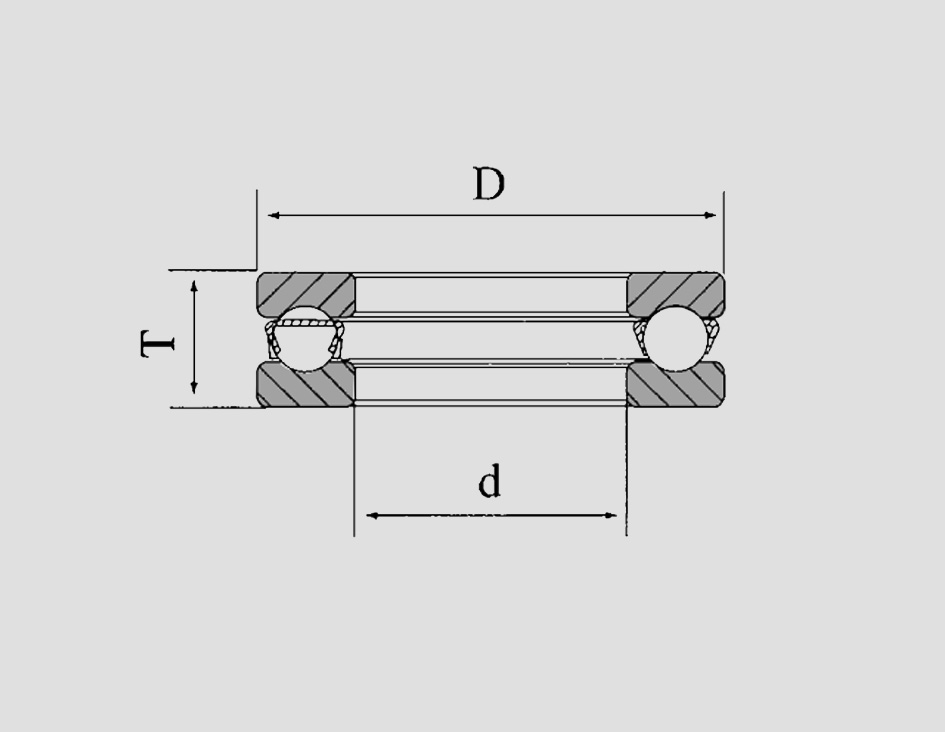

deep groove ball bearing

Sealed deep groove ball bearings are the unsung heroes of modern machinery, epitomizing reliability and efficiency across countless applications. Their robust design and practicality make them indispensable in industries such as automotive, aerospace, and industrial manufacturing. An exploration into their intrinsic qualities provides insight into why these components are trusted by engineers and technicians worldwide.

The authoritativeness of sealed deep groove ball bearings is borne out by their widespread usage across critical sectors. Leading manufacturers conduct rigorous testing to adhere to international standards such as ISO and ABEC. This compliance ensures that each bearing meets stringent quality benchmarks, fostering confidence among end-users. Moreover, innovations in seal technology contribute to enhanced energy efficiency, a crucial factor in industries aiming to reduce their carbon footprint. OEMs often rely on these bearings to ensure their equipment operates smoothly and reliably, testifying to their fundamental role in advancing industrial capabilities. Trustworthiness is further highlighted by testimonials and case studies that document the successful implementation of sealed deep groove ball bearings in demanding scenarios. Whether in high-speed motors or heavy-load conveyor belts, their ability to sustain performance without degradation is frequently cited. Such anecdotal evidence, combined with empirical data, reinforces the perception that these bearings are a prudent investment for any operation seeking stability and efficiency. In conclusion, sealed deep groove ball bearings exemplify the synthesis of engineering tradition and innovation. Their durability, efficient design, and adaptability render them crucial components in various industries, becoming linchpins in the productivity and success of modern machinery. As industries continue to evolve toward more sustainable and efficient practices, these bearings stand ready to meet the challenges of tomorrow, a testament to their enduring legacy of performance and reliability.

The authoritativeness of sealed deep groove ball bearings is borne out by their widespread usage across critical sectors. Leading manufacturers conduct rigorous testing to adhere to international standards such as ISO and ABEC. This compliance ensures that each bearing meets stringent quality benchmarks, fostering confidence among end-users. Moreover, innovations in seal technology contribute to enhanced energy efficiency, a crucial factor in industries aiming to reduce their carbon footprint. OEMs often rely on these bearings to ensure their equipment operates smoothly and reliably, testifying to their fundamental role in advancing industrial capabilities. Trustworthiness is further highlighted by testimonials and case studies that document the successful implementation of sealed deep groove ball bearings in demanding scenarios. Whether in high-speed motors or heavy-load conveyor belts, their ability to sustain performance without degradation is frequently cited. Such anecdotal evidence, combined with empirical data, reinforces the perception that these bearings are a prudent investment for any operation seeking stability and efficiency. In conclusion, sealed deep groove ball bearings exemplify the synthesis of engineering tradition and innovation. Their durability, efficient design, and adaptability render them crucial components in various industries, becoming linchpins in the productivity and success of modern machinery. As industries continue to evolve toward more sustainable and efficient practices, these bearings stand ready to meet the challenges of tomorrow, a testament to their enduring legacy of performance and reliability.

Next:

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024