10 月 . 06, 2024 05:59 Back to list

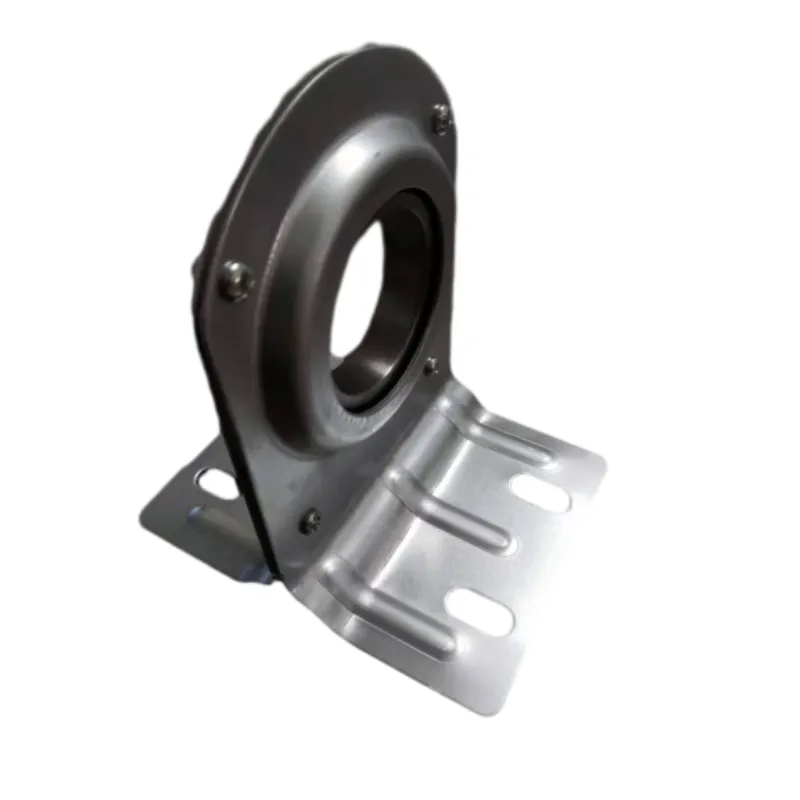

single row angular contact ball bearing

Understanding Single Row Angular Contact Ball Bearings

Single row angular contact ball bearings are widely used in various industrial applications due to their unique design and performance characteristics. These bearings are designed to support both radial and axial loads, making them suitable for a range of tasks where space is limited and precise alignment is crucial.

Design and Structure

The fundamental design of a single row angular contact ball bearing consists of an outer ring, an inner ring, a cage, and rolling elements, which are typically steel balls. The key feature of this bearing type is its angular contact arrangement that allows the balls to support loads at an angle to the shaft. This design enables the bearing to handle not only radial loads but also significant axial loads in one direction. Depending on the arrangement, the contact angle can vary, usually ranging from 15° to 40°. A larger contact angle results in a higher axial load capacity, which is an essential factor in determining the suitability of the bearing for specific applications.

Advantages

One of the primary advantages of single row angular contact ball bearings is their ability to accommodate combined loads. This capability is particularly beneficial in applications such as electric motors, pumps, machine tools, and various types of gearboxes, where both radial and axial forces are present. Additionally, because these bearings generally have a smaller footprint compared to other bearing types that can handle similar loads, they contribute to the compactness of machinery.

The rigidity of single row angular contact ball bearings is another significant advantage

. Their design enables them to maintain high precision even under load, making them ideal for applications requiring high-speed operation and minimal runout. Furthermore, the low friction characteristics of the balls rolling against the races allow for smoother operation and increased efficiency.Applications

single row angular contact ball bearing

Single row angular contact ball bearings are commonly found in numerous industries. In the automotive industry, they are used in wheel hubs, transmission systems, and electric motors. They are also prevalent in the aerospace sector, where lightweight and high-performance components are essential. Other industries, such as textiles, robotics, and machine tools, also rely on these bearings for efficient operation.

Because they can accommodate misalignment to a certain extent, single row angular contact ball bearings are suitable for applications where precise alignment may be challenging to maintain. This misalignment capability is achieved through their design, allowing for some degree of angular deflection without compromising performance.

Installation and Maintenance

Proper installation and maintenance are critical to maximizing the lifespan and performance of single row angular contact ball bearings. It is essential to ensure that the bearing is installed in the correct orientation, as reversing the orientation can lead to premature failure due to improper load distribution. Furthermore, maintaining the appropriate lubrication is crucial. Most bearings come pre-lubricated, but in high-speed or high-temperature applications, frequent lubrication maintenance may be necessary.

Regular inspections can also prevent potential issues. Checking for signs of wear, overheating, or abnormal noises can help identify problems before they lead to failures. By adhering to the manufacturer’s specifications and following best practices for maintenance, users can optimize the performance and reliability of their bearings.

Conclusion

In summary, single row angular contact ball bearings play a vital role in modern machinery and equipment across various industries. Their unique design, which accommodates both radial and axial loads, combined with their high precision and compact size, makes them indispensable components in applications requiring efficient and reliable operation. Understanding their characteristics, advantages, and proper maintenance techniques not only enhances their performance but also extends their lifespan, ultimately leading to increased productivity and cost savings in industrial environments. Whether in automotive applications or high-precision machinery, single row angular contact ball bearings continue to be central to advancing technology and engineering solutions.

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024