2 月 . 19, 2025 08:53 Back to list

Deep Groove Ball Bearings

In the world of mechanical engineering, single row deep groove ball bearings are often understated heroes, yet they play a pivotal role in various applications across numerous industries. Their design, characterized by deep raceway grooves, allows them to support radial and axial loads, rendering them indispensable in high-speed applications.

From an engineering perspective, the simple yet effective design of these bearings is paramount to their reliability and efficiency. The deep groove construction not only enables the accommodation of axial loads in both directions but also ensures higher tolerance to misalignment errors, a factor often lauded by engineering experts during mechanical design discussions. This structural robustness aligns with the high-quality standards trusted by industries globally. The expertise behind the manufacturing of these bearings cannot be overstated. Bearing manufacturers adhere to stringent quality controls, employing cutting-edge technology to ensure dimensional accuracy and superior material integrity. A deep dive into the manufacturing process reveals meticulous attention to detail, from material selection to the intricate heat treatment processes that enhance bearing lifespan. This authoritative approach speaks volumes about the bearing's performance under demanding conditions, fostering a sense of trust among industrial buyers. Credibility is further established through rigorous testing protocols, often mirrored in industry certifications and compliance with international standards such as ISO and AFBMA. These certifications attest to the reliability and efficiency of single row deep groove ball bearings, further instilling confidence among users. As the demand for efficiency and reliability in mechanical components grows, single row deep groove ball bearings remain at the forefront of innovation and application excellence. Their continued evolution is a testament to their foundational role in diverse industrial and consumer applications across the globe.

From an engineering perspective, the simple yet effective design of these bearings is paramount to their reliability and efficiency. The deep groove construction not only enables the accommodation of axial loads in both directions but also ensures higher tolerance to misalignment errors, a factor often lauded by engineering experts during mechanical design discussions. This structural robustness aligns with the high-quality standards trusted by industries globally. The expertise behind the manufacturing of these bearings cannot be overstated. Bearing manufacturers adhere to stringent quality controls, employing cutting-edge technology to ensure dimensional accuracy and superior material integrity. A deep dive into the manufacturing process reveals meticulous attention to detail, from material selection to the intricate heat treatment processes that enhance bearing lifespan. This authoritative approach speaks volumes about the bearing's performance under demanding conditions, fostering a sense of trust among industrial buyers. Credibility is further established through rigorous testing protocols, often mirrored in industry certifications and compliance with international standards such as ISO and AFBMA. These certifications attest to the reliability and efficiency of single row deep groove ball bearings, further instilling confidence among users. As the demand for efficiency and reliability in mechanical components grows, single row deep groove ball bearings remain at the forefront of innovation and application excellence. Their continued evolution is a testament to their foundational role in diverse industrial and consumer applications across the globe.

Latest news

-

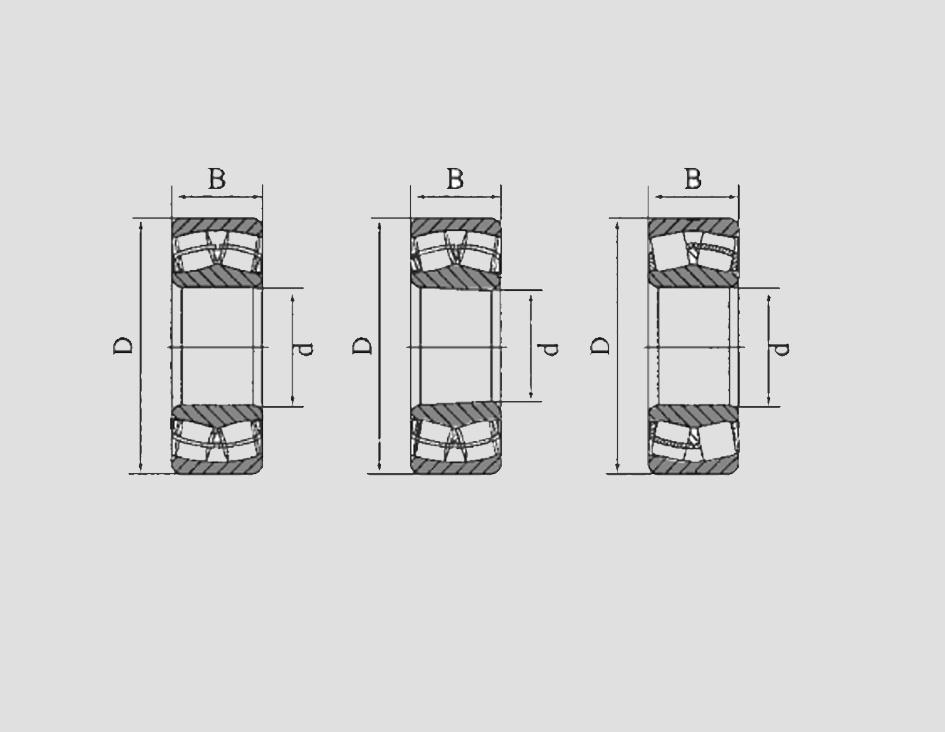

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024