11 月 . 01, 2024 20:17 Back to list

Spherical Plain Bearing Size Guide and Specifications for Various Applications

Understanding Spherical Plain Bearings A Guide to Sizing

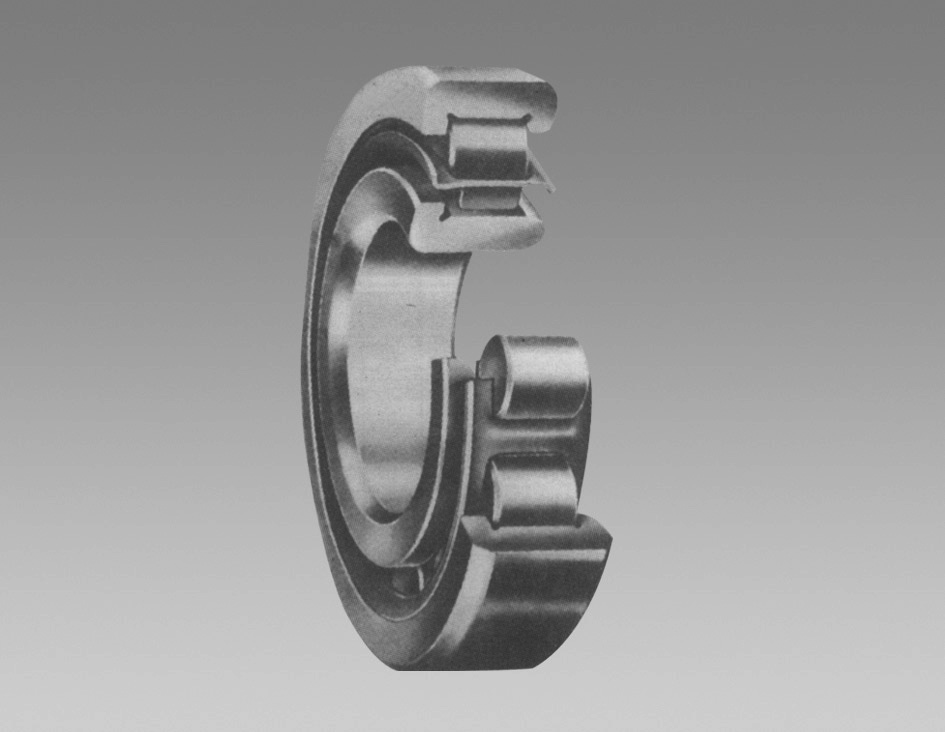

Spherical plain bearings are integral components in various mechanical systems, especially where rotational movement is involved. These bearings are designed to accommodate misalignments and provide a low-friction surface for movement. To ensure optimal performance and longevity, it is crucial to select the correct size of spherical plain bearing for your specific application. This article will explore the importance of size charts and how to effectively utilize them.

Firstly, a spherical plain bearing consists of an inner ring with a spherical convex outer surface and an outer ring with a spherical concave inner surface. This unique design allows for angular movements while maintaining a reliable load-bearing capability. The range of applications for these bearings is vast, from automotive to aerospace and industrial machinery.

When it comes to sizing, spherical plain bearing size charts are invaluable resources. These charts list various parameters, including outer diameter, inner diameter, and width, alongside the bearing's load capacity and performance specifications. By referring to these charts, engineers and technicians can make informed decisions when selecting bearings that match their application requirements.

spherical plain bearing size chart pdf

To utilize a spherical plain bearing size chart effectively, one must first identify the specific needs of the application. Consider factors such as load conditions, environmental conditions, and the type of movement required. Next, determine the dimensional requirements by measuring the space where the bearing will be installed. Ensuring that the bearing fits correctly is essential to avoid excessive wear or potential failure.

After gathering these details, consult the size chart to find a suitable bearing that meets the required specifications. Pay close attention to the load ratings provided, as they indicate the bearing's capacity to handle various forces without failure. Selecting a bearing with an appropriate load rating is critical to ensuring reliability and performance over time.

Moreover, beyond just size and load considerations, it is important to assess additional factors such as material, lubrication methods, and mounting styles. Different operating environments may necessitate specific material choices to withstand corrosion, temperature extremes, or other challenges.

In conclusion, understanding how to read and apply spherical plain bearing size charts is essential for anyone working with mechanical systems. By carefully considering the application requirements and consulting the appropriate charts, users can select the right bearings, ensuring efficient operation and extended service life. Investing time in this process not only enhances performance but also reduces the risks associated with bearing failure, ultimately saving costs and improving system reliability.

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024