11 月 . 02, 2024 12:43 Back to list

taper bearing cone

Understanding Taper Bearing Cones

Taper bearing cones play a crucial role in various mechanical systems, providing support and facilitating smooth rotation for loads in applications ranging from automotive to industrial machinery. Unlike traditional bearings, taper bearings are designed to accommodate both radial and axial loads, making them an essential component in many moving systems.

What is a Taper Bearing Cone?

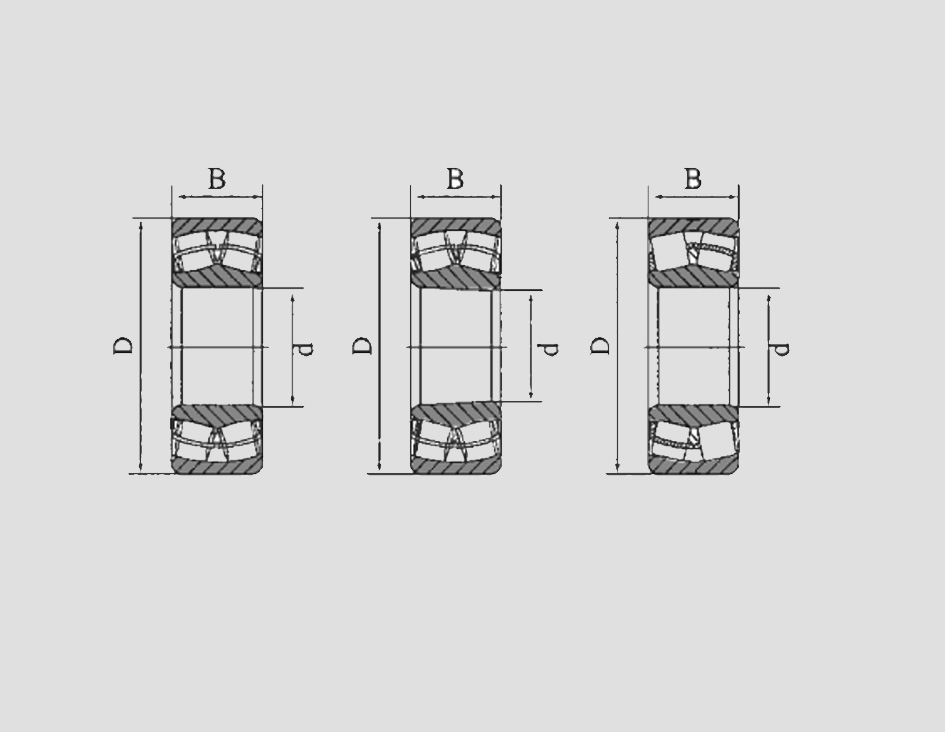

A taper bearing cone consists of an outer ring, a cone (inner ring), a set of rolling elements (typically tapered rollers), and a cage. The cone's tapered design allows for improved load distribution and reduced stress on the bearing surfaces. This shape enables the bearing to handle larger axial loads compared to non-tapered bearings, making it a preferred choice in heavy-duty applications.

Functions and Applications

Tapered roller bearings are extensively used in different industries due to their versatility. In automotive applications, they are commonly found in wheel hubs and transmissions, allowing vehicles to handle immense loads while maintaining stability and control. In industrial machinery, taper bearings are integral to conveyor systems, gearboxes, and construction equipment, where they enhance the operational efficiency and longevity of the machinery.

taper bearing cone

The flexibility of taper bearings also extends to their ability to adjust to misalignment. This characteristic is particularly advantageous in applications where precise alignment is challenging. Furthermore, taper bearings can be disassembled and reassembled, allowing for easy maintenance and replacement. This feature reduces downtime and improves overall productivity.

Installation and Maintenance

Proper installation of taper bearing cones is vital for their performance and lifespan. It requires precise bearing preload, ensuring that the rollers are firmly seated without excessive tightness that could cause premature wear. Regular maintenance, including periodic inspections and lubrication, is also essential to prevent failure. Over time, contaminants can accumulate, and lubrication may degrade, leading to increased friction and wear. Therefore, maintaining a clean environment and following the manufacturer's guidelines is imperative.

Conclusion

In summary, taper bearing cones are indispensable components in a wide array of applications, offering robust support and efficient load handling. Their unique design allows them to manage both radial and axial loads effectively, making them ideal for high-performance environments. As industries continue to evolve, the demand for reliable and efficient bearing solutions like taper bearings will only increase. Understanding their functionality, installation, and maintenance will ensure optimal performance and longevity in various mechanical systems.

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024