11 月 . 01, 2024 21:40 Back to list

taper bearing size chart pdf

Understanding Taper Bearing Sizes A Comprehensive Overview

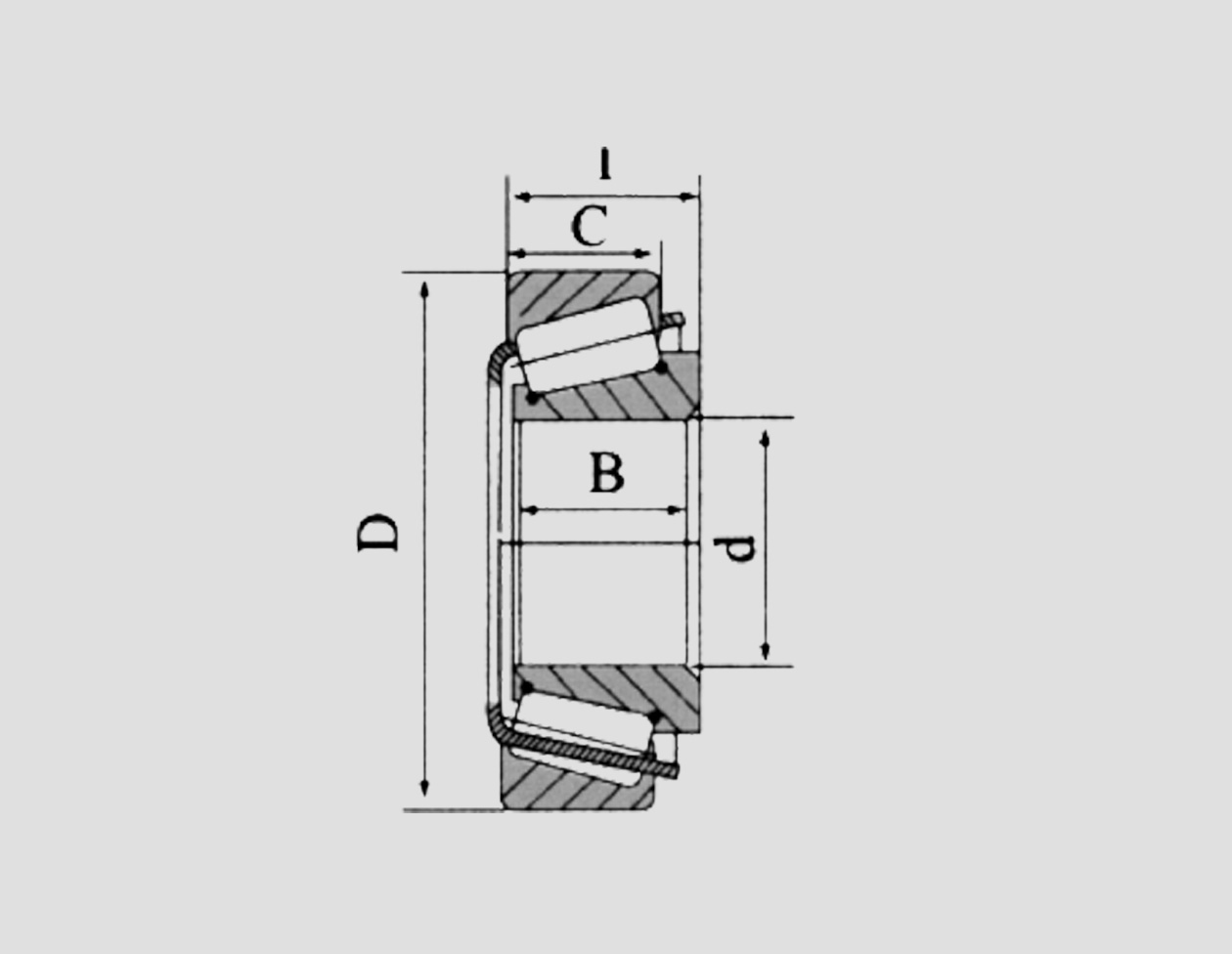

Taper bearings, commonly used in various mechanical applications, are essential for ensuring smooth rotation and load distribution. Understanding their sizes and specifications is crucial for engineers and maintenance professionals alike. A key resource for this information is the taper bearing size chart, often available in PDF format, which provides critical details needed for selecting the right bearing for a specific application.

Taper bearings, characterized by their conical shape, are designed to handle both radial and axial loads. This makes them suitable for a wide range of uses, from automotive wheels to industrial machinery. The design of taper bearings allows for an optimal contact surface between the rolling elements and the raceways, enhancing performance and longevity.

Understanding Taper Bearing Sizes A Comprehensive Overview

One of the critical components of the taper bearing size chart is the bearing number. Each bearing is assigned a unique number that corresponds to its dimensions and load capabilities. This classification helps engineers and technicians quickly identify the correct bearing for a given task without having to access individual specifications repeatedly.

taper bearing size chart pdf

Furthermore, the chart often catalogs various bearing types and their respective applications. For example, some taper bearings are designed specifically for heavy-duty applications, while others may be more suitable for lighter loads. Understanding the context in which a bearing is used will help in selecting the appropriate size and type, ultimately leading to improved efficiency and reduced wear.

In addition to dimensions and ratings, the taper bearing size chart may also include information on tolerance levels, which indicate how much variation in size is acceptable. This information is particularly important when bearings are being fitted into tight spaces or when precise alignment is necessary for optimal performance.

It is also worth noting that proper installation and maintenance are critical factors that affect the lifespan of taper bearings. Users should be aware that even the best bearing can fail if not installed correctly or if subjected to conditions beyond its rated capacity. Regular inspections and adherence to maintenance schedules can help mitigate these risks, ensuring continued performance and reliability.

In conclusion, the taper bearing size chart serves as an invaluable tool for anyone involved in the selection or maintenance of taper bearings. By understanding the various parameters provided in the chart, engineers and technicians can make informed decisions that optimize performance and extend the life of mechanical systems. Whether in automotive applications or heavy machinery, the right taper bearing is crucial for achieving operational efficiency and reliability.

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024