3 月 . 05, 2025 02:46 Back to list

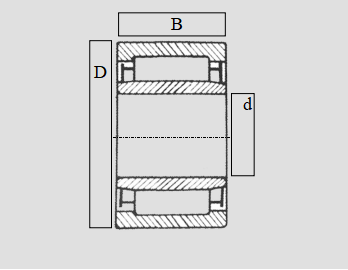

deep groove ball bearing

Deep groove ball bearings are ubiquitous in various industries due to their versatility and high performance. They are the most common type of bearing, found in applications ranging from household appliances to high-speed automotive engines. To fully optimize their performance, understanding the nuances of deep groove ball bearing calculations is crucial.

Deep groove ball bearings are subject to axial and radial loads, and calculations must account for both to ensure balanced operation. Radial load acts perpendicular to the shaft, whereas axial load occurs parallel to the shaft. Bear in mind that excess axial loads can lead to increased friction and wear; therefore, the bearing must be accurately fitted and aligned. It's also imperative to consider the installation and environment during calculations. Improper installation can lead to misalignment, excessive vibration, or additional stress on the bearing, which can induce failure. Environmental considerations, such as exposure to dust, moisture, or corrosive substances, necessitate specific seal or shield configurations, which should be included in preliminary calculations. Real-world experience underscores the importance of regular monitoring and maintenance schedules based on the initial bearing calculations. Regular inspections and condition monitoring can preempt many issues, extending the operational life of the bearings. Ultimately, mastering deep groove ball bearing calculations involves a blend of theoretical knowledge and practical application, ensuring that bearings fulfill their intended roles across applications. By optimizing these calculations, businesses can enhance product reliability, efficiency, and customer satisfaction, establishing their authority and trust within their respective industries.

Deep groove ball bearings are subject to axial and radial loads, and calculations must account for both to ensure balanced operation. Radial load acts perpendicular to the shaft, whereas axial load occurs parallel to the shaft. Bear in mind that excess axial loads can lead to increased friction and wear; therefore, the bearing must be accurately fitted and aligned. It's also imperative to consider the installation and environment during calculations. Improper installation can lead to misalignment, excessive vibration, or additional stress on the bearing, which can induce failure. Environmental considerations, such as exposure to dust, moisture, or corrosive substances, necessitate specific seal or shield configurations, which should be included in preliminary calculations. Real-world experience underscores the importance of regular monitoring and maintenance schedules based on the initial bearing calculations. Regular inspections and condition monitoring can preempt many issues, extending the operational life of the bearings. Ultimately, mastering deep groove ball bearing calculations involves a blend of theoretical knowledge and practical application, ensuring that bearings fulfill their intended roles across applications. By optimizing these calculations, businesses can enhance product reliability, efficiency, and customer satisfaction, establishing their authority and trust within their respective industries.

Next:

Latest news

-

Unlocking Efficiency with Spherical Roller Bearings

NewsOct.29,2024

-

The Ultimate Guide to Thrust Ball Bearings

NewsOct.29,2024

-

The Power of Thrust Roller Bearings: Engineered for Excellence

NewsOct.29,2024

-

The Power of Deep Groove Ball Bearings for Your Application Needs!

NewsOct.29,2024

-

The Power and Performance of Cylindrical Roller Bearings

NewsOct.29,2024

-

High-Quality Ball Bearing Manufacturing Machines

NewsOct.29,2024